下载PDF

U.S.-based Global Manufacturer Seamlessly Migrates to NextGeneration SDN Data Centers with NETSCOUT

技术

- 基础设施即服务 (IaaS) - 云计算

适用功能

- 离散制造

- 商业运营

用例

- 工厂可见化与智能化

- 基础设施检查

服务

- 云规划/设计/实施服务

- 系统集成

挑战

这家总部位于美国的全球制造商由于数据中心陈旧而面临高昂的运营费用,每月高达数百万美元。该公司需要整合其数据中心,实施软件定义网络解决方案 (SDN),实现服务自动化,更快地部署应用程序,并引入云战略以降低运营费用 (OPEX)。最大的挑战之一是在极其紧迫的时间内从四个传统数据中心过渡到两个新数据中心。任何延迟都会对实现预计的成本节约产生负面影响。此外,整合后的数据中心需要快速分类任何问题的能力。这可能会导致生产服务延迟和数百万美元的损失。

关于客户

客户是一家总部位于美国的全球制造商,为各大洲数百万消费者提供产品。该公司在全球拥有数万名员工和制造工厂。该公司是全球标志性企业,热衷于在其运营的每个角落利用技术创新。为了满足全球运营需求,这家大型制造商认识到成为其行业世界级技术领导者的重要性。然而,过时的数据中心导致的过高运营费用每月高达数百万美元。该公司管理层决定,必须重新规划其全球制造业务,以便在世界任何地方设计、制造、销售和维修其产品。

解决方案

为了解决数据中心迁移和生产服务方面的挑战,IT 团队向 NETSCOUT 求助。nGeniusONE 服务保证平台采用自适应服务智能™ (ASI) 技术,与战略性地部署在服务交付路径上的 InfiniStream 设备相结合,用于监控和关键分析。他们还部署了 nGenius 数据包流交换机,该交换机的架构旨在同时为 InfiniStream 设备和其他安全工具提供可视性。在开始迁移到公司新的生产数据中心之前,NETSCOUT 解决方案用于测试和验证预生产应用程序中心基础设施 (ACI) 环境。该解决方案为制造生产应用程序提供了对新连接点和互联网连接的实时监控,这对公司在全球的运营至关重要。

运营影响

数量效益

相关案例.

Case Study

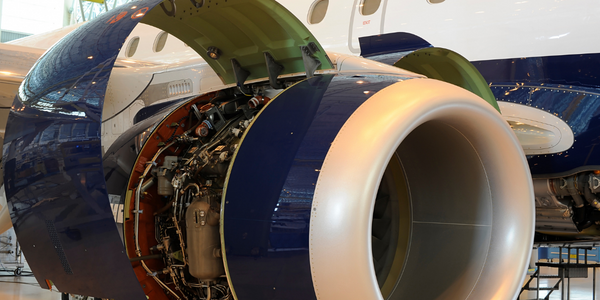

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.

Case Study

AUDI AG 20% PRODUCTIVITY IMPROVEMENT

In the automotive industry, niche products are becoming more and more important. The automobile industry has changed considerably over the past few years. No doubt: to remain competitive, instant reaction to specific customer requests is of utmost importance. In a parallel to the growing individualization of our society, the range of models available from Audi has increased as well.

Case Study

Automotive Component Manufacturer Improves with Datonis IoT Solution

As a part of their Industry 4.0 initiative, the customer primarily wished to leverage IoT for maximizing operational efficiencies, productivity, reducing the energy footprints and maximizing capacity utilization. But there were several challenges at the outset:Firstly, the customer had multiple assembly lines with a diverse set of machines, systems and sensors, all communicating on different protocols. As such, primarily they needed a partner who could connect diverse set of assets on to a single platform and make use of underutilized ‘dark’ data.Secondly, the amount of data, data types and their applications was so vast, that the platform handling it, needed to be scalable and flexible.Lastly, Varroc faced the typical challenge of innovating in ‘Brownfield’ markets – wherein the real bottleneck is in integrating IoT in tandem with both the new and legacy equipment without any further CAPEX for asset substitution.

Case Study

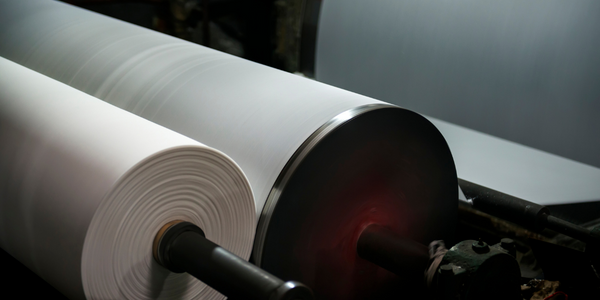

Improving productivity and quality in Textiles

VISIBILITY - Currently unable to see amount of power consumed per machine or plant; need to account for energy used per batch. WASTE - 10% of product fails quality standards, unable to identify point of failure (initial spinning, weaving, final processing, etc). INACCURACY - Acquiring OEE measurements and compiling them is a manual process, which lacks visibility into all parts of the production process and is error-prone. LACK OF INTEROPERABILITY - Outdated machinery still has long, effective lifespans but needs to connect to newer, digital assets

Case Study

IoE Increases Operational Efficiencies and Improves Energy Management

For many manufacturing companies today, the opportunity to connect people, process, data, and things created by the Internet of Everything (IoE) presents a new way to look at factory automation. The opportunity for digital innovation often arises when a company is expanding capacity or building a new production facility. Mahindra and Mahindra, one of India’s leading automakers, seized the opportunity to deploy a connected factory of the future at their new Chakan facility.