下载PDF

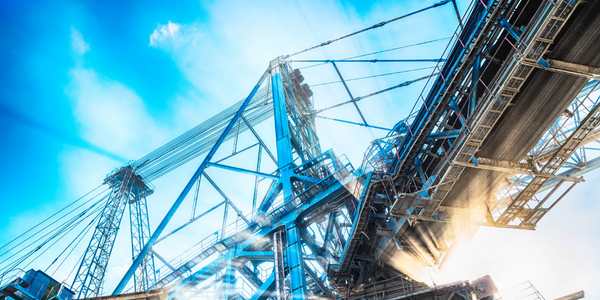

Upgrading a Coal Transfer Chute: Hatch Deploys Altair EDEM BulkSim Solution for Mining

技术

- 基础设施即服务 (IaaS) - 云计算

- 传感器 - 液体检测传感器

适用行业

- 生命科学

- 矿业

适用功能

- 产品研发

- 质量保证

用例

- 施工管理

- 实验自动化

服务

- 测试与认证

挑战

Hatch Ltd. 是一家为采矿、冶金、能源和基础设施行业提供工程、项目和施工管理服务的全球供应商,该公司签订合同升级现有选煤厂的输送机转运点。客户需要升级以适应计划的产量增加。输送机运载粗煤,上面有一层含水量较高的滤饼。现有的溜槽很容易出现这种“粘性”滤饼的材料堆积,在流量激增时经常发生堵塞,并导致代价高昂的停机。尽管输送机相对较小,速度为 1,200 吨/小时,但它对于确保卡车装载箱的稳定产品吞吐量至关重要。

关于客户

Hatch Ltd. 是一家为采矿、冶金、能源和基础设施行业提供工程、项目和施工管理服务的全球供应商。他们签订合同升级现有选煤厂的输送机转运点。客户需要升级以适应计划的产量增加。输送机运载粗煤,上面有一层含水量较高的滤饼。现有的溜槽很容易出现这种“粘性”滤饼的材料堆积,在流量激增时经常发生堵塞,并导致代价高昂的停机。

解决方案

Hatch 部署了 EDEM BulkSim 解决方案(包括材料测试和 DEM 材料模型校准服务)来重新设计传送溜槽。对代表现场实际材料的产品煤和滤饼的实际样品进行了动态流动测试。使用云计算平台上的自动参数扫描,通过将物理测试结果与模拟进行比较,快速校准 DEM 材料模型。 Hatch 的新转运点设计包括一个铰接在顶部的翻转门,用于将水流引导至两条流路之一。设计选项的虚拟性能测试是在一系列材料流动条件下进行的,包括高粘性材料。这使得 Hatch 能够快速选择用于详细设计生产的最佳配置。

运营影响

数量效益

相关案例.

Case Study

Underground Mining Safety

The goal was to produce a safety system to monitor and support underground mining operations; existing systems were either too simple (i.e. phone line) or overly complex and expensive, inhibiting deployment, and providing little-to-no support in event of an accident. Given the dangerous nature of the mining work environment and the strict regulations placed on the industry, the solution would have to comply with Mine Safety and Health Administration (MSHA) regulations. Yet the product needed to allow for simple deployment to truly be a groundbreaking solution - increasing miner safety and changing daily operations for the better.

Case Study

Mining Firm Quadruples Production, with Internet of Everything

Dundee Precious Metal’s flagship mine, in Chelopech, Bulgaria, produces a gold, copper, and silver concentrate set a goal to increase production by 30%. Dundee wanted to increase production quality and output without increasing headcount and resources, improve miner safety, and minimize cost.

Case Study

Fastenal Builds the Future of Manufacturing with MachineMetrics

Fastenal's objective was to better understand their machine downtime, utilization, quality issues, and to embrace cutting-edge manufacturing technology/process improvement capabilities to bring their team to the next level. However, there was a lack of real-time data, visualization, and actionable insights made this transition impossible.

Case Study

Joy Mining Systems

Joy equipment faces many challenges. The first is machine integration and control. The business end of the machine has a rapidly-spinning cylinder with 6-inch diamond-studded cutting teeth. It chews through rock at rates measured in tens of tons per minute. The system grinds through the rock in front, creating a rectangular mine tunnel. Hydraulic lifters support the ceiling as the machine moves forward. Automated drills and screws drive 3-ft long screws into the ceiling to stabilize it. The rock and coal fall into a set of gathering "fingers" below the cutting cylinder. These fingers scoop up the rock and coal and deposit it onto a conveyor belt. The conveyor passes under the machine and out the back. A train of conveyor belt cars, up to a mile long, follows the cutter into the mine. The rock shoots along this train at over 400 feet per minute until it empties into rail cars at the end. Current systems place an operator cage next to the cutter. Choking dust (potentially explosive), the risk of collapse and the proximity of metal and rock mayhem make the operator cage a hazardous location.

Case Study

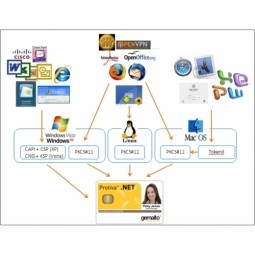

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data