Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,158)

- (2,048)

- (1,256)

- (927)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,461)

- (1,423)

- View all 42 Industries

- (5,782)

- (4,114)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,392)

- (2,982)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,927 case studies

|

ZumIQ APPLICATION ENVIRONMENT: REMOTE MONITORING OF FIELD ASSETS

FreeWave Technologies

|

|

Connecting the EY Building

- Multiple A/C systems to be monitored through single central monitoring system. - Monitor Status of UPS, generator and switch gear status. Both digital and analog signals. - Monitor building for low voltage conditions and power usage. - Monitor for water leak detections. - Monitor the actual operation of HVAC units to include compressor amperages, refrigerant pressures, fan and filter status. - Implement open protocol Building Automation System for future multi-vendor expansion. - Monitoring and alarming of Space Temperature within a prescribed limits. The Ernst & Young's primary concern was a power loss and high space temperatures in the both the data center and LAN rooms. The UPS or generator would start and all A/C units would cycle on and off with no delay and this would put a drain on the power supply. E&Y sought to implement an integrated system that would not only effectively monitor, but also time out and stage the A/C system restart. They were also looking for a system that allowed for future expansion of the remote alarm monitoring.

|

|

TU Darmstadt students make packing smart with ThingWorx

ThingWorx

An Advanced Design Project toward IoT was open to a handful ofundergraduate students in TU Darmstadt from various backgrounds. The team’s goal was to develop an IoT solution by semester’s end.Based on their personal experience and the survey results—which told them 85% of people had forgotten to pack something important on a trip—they decided to apply the IoT to the world of travel. Armed with ThingWorx and PTC University eLearning Libraries, they began to develop the project idea and scope.

|

|

Smarter, Safer, and More Cost-Efficient Lighting Environments with Enlight

Enlight

Few areas draw as much attention, time, and budget scrutiny as the network of thousands of street lights deployed in every urban environment. From safety concerns arising from broken bulbs to escalating energy costs and maintenance headaches, street lights are a hot-button issue for government administrators, law enforcement personnel, and, of course, constituents. Furthermore, Cities are increasingly handing-over street lighting operations to external partners under a determined Service Level Agreement, which performance is appraised using Key Performance Indicators that have to be measured and recorded. Aiming to turn this challenge into opportunity, Enlight – a name that underscores the company’s commitment to energy and lighting solutions – has devoted its business to developing and producing smart networks of street lights in urban environments – from streets and avenues to parks, playgrounds, and plazas. According to Miguel Lira, general manager for Enlight, new technologies continue to evolve and municipalities want to do more than turn lights on and off. They want full smart solutions for monitoring and controlling energy, and managing maintenance. “At first, we just provided basic services to manage street lights – just turning them on and off,” he said, “but as new technologies emerged, we were soon integrating hardware, software and finally producing smart lighting devices. But as the sophistication of these devices grew, so did our need for bandwidth to transmit more secure data at faster speeds and with greater reliability.” Previously, Enlight installations tapped into the actual electrical cable power the street lights as the communication channel. “At the time, RF communication was not reliable, stable, or well-developed,” Lira said, “but the powerline was noisy and not fully reliable.”

|

|

Carestream: Market Disruption and Improved Customer Relationships

PTC

Medical Imaging Healthcare imaging centers provide diagnostic imaging from computed tomography (CT), magnetic resonance imaging (MRI), digital mammography and other advanced imaging systems to physicians in digital format as well as printed on radiographic film, tailored to the referring physician’s requirements. The global market for diagnostic print services is mature and increasingly commoditized due to consolidation into a few large vendors that have heightened customer’s sensitivity to total cost of ownership. Carestream sought a new and innovative way to improve the customers total cost of ownership through consumption based services that has resulted in the creation of a new business model that has disrupted this commoditized market and changed its dynamics in Carestream’s favor. Healthcare Information Systems Carestream also had an opportunity to optimize critical maintenance and performance of its Healthcare Information Solutions (HCIS) portfolio, which simplifies clinical data management throughout different imaging departments. As the IT ecosystem expands from just back-end infrastructure to more bed-side diagnostics or patient facing, maintenance and system uptime becomes even critical to healthcare providers.

|

|

Perishable Goods Delivered Without Peril

KORE Wireless

Specializing in shipping perishable goods via multi-day trips on someone else’s truck could be challenging and costly. Weather, unusual conditions, cross-border customs controls and lack of standardization among trucks to hold and maintain temperature are just a few of the challenges Allen Lund faces every day.

|

|

IoT for Civil Architecture and Artistic Monuments

Some public works, civil and heritage buildings have challenges in detecting abnormal structure movements in real time to maintain control of critical structure points, logging and analyzing data of all the structural properties to identify anomalies and accessing promptly to the data without the need of an on-site intervention.

|

|

Mondi Implements Statistics-Based Health Monitoring and Predictive Maintenance

MathWorks

The extrusion and other machines at Mondi’s plant are large and complex, measuring up to 50 meters long and 15 meters high. Each machine is controlled by up to five programmable logic controllers (PLCs), which log temperature, pressure, velocity, and other performance parameters from the machine’s sensors. Each machine records 300–400 parameter values every minute, generating 7 gigabytes of data daily.Mondi faced several challenges in using this data for predictive maintenance. First, the plant personnel had limited experience with statistical analysis and machine learning. They needed to evaluate a variety of machine learning approaches to identify which produced the most accurate results for their data. They also needed to develop an application that presented the results clearly and immediately to machine operators. Lastly, they needed to package this application for continuous use in a production environment.

|

|

UAV for Construction Sites

Leica Geosystems

The Swiss power company Axpo is building a new, underground pumped storage plant – the largest in the country – in the Canton of Glarus. In the future, the plant will guarantee the future electricity supply to northeastern and central Switzerland. The plan is for the plant to pump water from Lake Limmernsee back up to Lake Muttsee – an altitude difference of 630 metres – where it can be used again to generate electricity when required. This large-scale project, which involves investment costs of around 1.7 billion euros and is expected to take the best part of five years to complete, will employ up to 500 people at various construction sites. The plant should start to deliver electricity in 2015/2016. Hundreds of thousands of cubic metres of soil and rock will have to be removed to build the tunnels and caverns for the pumped storage plant. Most of this spoil will be transported to the Muttenalp mountain by cable car and used to build the dam, which will be more than a kilometre long and rise to a maximum height of 36 metres. The rest of the material will be deposited in front of the existing Limmern dam. The company needs to survey the surrounding before implementing the project.

|

|

Energy Savings of Up to 40% with Energy Data Management solution

Vodafone

Faced with rising global energy costs, and determined to fulfil its obligation to minimise its carbon footprint, Vodafone decided it needed a solution that would manage the way it consumes energy more proactively. To get the intelligence and global scale that it needed, Vodafone soon discovered it would need to build the solution itself.

|

|

New Sun Road Connects Uganda to Clean and Reliable Energy

Digi

New Sun Road is a registered California Benefit Corporation committed to implementing solutions to climate change and global energy poverty. This group of talented engineers is partnering with Ugandan green energy startup GRS Commodities to deliver reliable and clean power to the Ssese Islands in Lake Victoria, Uganda. The goal of the pilot system is to provide affordable and reliable solar powered electricity to businesses on Kitobo Island.Although no small feat, deploying the solar power grids is likely the simplest part of the solution. Solar was the obvious choice for the power source because it is economical and relatively simple to deploy.The primary difficulty lies in managing the energy grid and ensuring proper maintenance without having to be on-site at every location. The capability to remotely monitor the grid will enable New Sun Road to expand their service across the Ssese Islands in a more efficient manner since each grid can be monitored from one central location. But, in remote areas, where communication options are limited, how do you remotely monitor and manage a smart solar power grid?Without a local ISP, this can be a complex challenge, so the team decided to enable remote connectivity over the global cellular network.In addition to communication challenges, another major difficulty New Sun Road had to overcome was finding a device capable of withstanding the high temperatures within their network hubs. The device would be residing within a NEMA enclosure in direct sunlight, so the capability to function under extremely high temperatures was a must.

|

|

Connected Street Lighting in Los Angeles

The 215,000 street lights in Los Angeles include more than 400 different styles distributed across 7,500 miles of roadway. Maintenance has traditionally depended on crews who scout the streets at night to identify outages— that, and calls from citizens. The bureau handles 40,000 such calls per year. They needed to find new technology that could improve customer service, make people feel safer, and create a more livable city.

|

|

Samsonite Track&Go

Accent Systems

Travellers spend their lives discovering new places and meeting new people from all around the world. It can be such a wonderful experience, but sometimes it can turn into a disaster when your luggage gets lost. In 2014 alone, more than 24 million pieces of baggage were lost. Fortunately, 95% of them were found and returned to their owners. However, that leaves more than 1 million items of baggage that have never been recovered.

|

|

Using Data to Make Operators and Maintenance Staff Efficient

Microsoft

Some of Elipse's customers have very large plants, and when the technicians are out in the plant, they cannot see the status of plant instrumentation. When doing calibrations or inspections, they have to radio back to the control room, which slows the work and can extend downtime.

|

|

Tradition of Innovation for a Future of Success

SAP

Schaidt Innovations was purely a production site with no ERP IT infrastructure when started. So the company needed an ERP system and there was no time for a long, drawn-out implementation. And Schaidt did not have the resources or funding to invest in ERP IT development, customization, and support.

|

|

Digital Twin

Faststream Technologies

The client looked for real-time visibility for the health status of the Early Production System.More signals were processed, and human intervention was unable to find anomalies that lead to performance abasement.The yield and profitability of the projects decreased as there was a lack of sensor intelligence or apparatus detections.

|

|

Preserving Security and Operator Safety

PTC

To improve customer satisfaction by minimizing downtime of automated optical inspection machines while preserving security and safety.

|

|

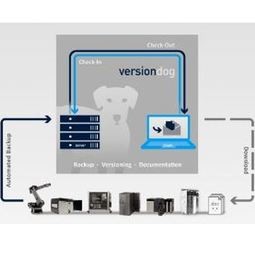

Logistics processes in safe hands

AUVESY-MDT

The latest logistics and automation technologies that help to safeguard work processes in large warehouses with complex, around-the-clock global distribution networks require regular changes and improvements to function optimally. At the same time, these modifications also increase the risk of errors or even production stoppages, which are unfavorable situations.

|

|

3D Printed Prototypes Streamline Equipment Introduction

3D Systems

Vauxhall set out to introduce a modified process hanger with a new part that would be used to support each vehicle body throughout the production process. This part is a critical piece and had to perfectly fit both the machinery and the auto body to create correct clearances and avoid damage during production.

|

|

Tetro Factory's Efficiency Improvements

Matics

Tetro factory had the following challenges: - Controlling the production flow, tracing mistakes and optimizing performance. - Running a fully integrated knowledge-based business with systems that work seamlessly together. - Centralizing manufacturing production data into one system that can be viewed and analyzed from a single-point-of-entry. - Pinpointing in real-time which stations are compromising production and what can be done to restore and improve efficiency. -Implementing preventative maintenance and ensuring minimum downtime. - Monitoring energy consumption and optimizing material consumption per product.

|

|

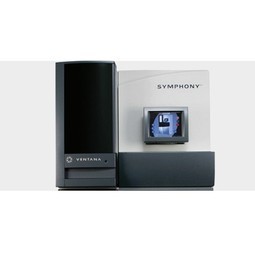

Improving Instrument Recovery Time and Reducing Downtime

PTC

While in the midst of developing SYMPHONY®, a fully automated slide staining system for standard Hematoxylin and Eosin (H&E) staining, Ventana realized that they required a remote service solution to ensure that customers received an exceptional level of service. However, with a tight timeline to develop and launch this new product, there was some reluctance to integrate additional software. “There was some internal reluctance toward implementing the remote service technology with our SYMPHONY instrument given the short timeframe,” explains Greg Dameron, Director of Development at Ventana. “In fact, the executive team informed me that if the software would delay the SYMPHONY launch by even one day, then we would not implement it at all.” The company began evaluating commercial remote service offerings, seeking a solution that would provide value to customers without disrupting system stability. “Our products are based on stability, so we needed the remote service technology to be stable as well,” says Dameron. Ventana sought to reduce instrument downtime to fewer than 24 hours by remotely monitoring all field instrumentation on a 24/7 basis. This would enable the abilities to remotely diagnose and repair issues, provide “over-the-shoulder” troubleshooting and training for users, and track inventory to automatically replenish reagents in real time. “We felt strongly that delivering remote service would help us achieve a response time that we could not otherwise meet,” says Dave Flaten, Vice President and General Manager of the Primary Staining business unit at Ventana. “We believed that it would become an integral part of the product line.”

|

|

Star Refrigeration

Adroit Technologies

Star Refrigeration’s TELSTAR control system uses the LonWorks® network. This fieldbus network has become the standard for the building management industry, which encompasses refrigeration and air conditioning. Star’s Electronic Systems Manager and Senior Development Engineers needed to source a SCADA HMI which would fulfil their data acquisition and monitoring requirements and match their networking needs. The ability to fit into LonWorks was a key requirement for the project. Adroit adopted a close, co-operative approach and adapted their SCADA HMI by writing a comprehensive interface to the LonWorks network. The Adroit SCADA HMI monitors data and performance of industrial refrigeration plants manufactured and installed by Star. In addition, the system provides an operator interface for altering plant control, with appropriate levels of security, using the TELSTAR system. The software is now the main data monitoring operator interface for TELSTAR, and is used in applications ranging from ice rinks and air conditioning to pharmaceuticals, distilling, fish processing and food storage. Star’s Development Engineers received training from Adroit, attending Adroit 2 + 1, a fast track course designed for system integrators and experienced end users, and the Adroit Advanced course. Star Refrigeration staff are now able to carry out their own in-house Adroit training for operators.

|

|

Transforming Public Transit in Austria

Cisco

• Enhance safety for trams and passengers • Deliver an innovative passenger experience • Improve operational efficiency with better insight

|

|

Business Analytics Deliver Operational Intelligence

Splunk

iRhythm was founded to provide patients an affordable alternative for monitoring heart rhythms, one that helps avoid the complexities, inefficiencies and lack of cost-effective monitoring options. With its single-use adhesive Zio Patch, an ECG rhythm monitor that can be used continuously for up-to-14 days, iRhythm has addressed key unmet clinical needs in the field of ambulatory cardiac monitoring. In order to keep pace with its rapid growth and limited resources, iRhythm required an efficient and effective way to monitor business processes, establish baseline performance across the entire operation and continue to track that performance to support the company's value-driven, high-volume business model.

|

|

Property Management Firm Creates Energy-Efficient Smart Building

The Internet of Things (IoT), in which people, process, data, and things are connecting at unprecedented scope and scale, is making precision network connections more essential than ever before. The next generation of real estate and building services is turning workplaces and residential spaces into environments that are personalized, efficient, functional, and profitable.The innovative technology behind this type of transformation can be found in Cisco® Smart+Connected Real Estate solutions

|

|

MICROMEDIA’S ALERT ASSISTS AIR LIQUIDE’S SCADA SYSTEM FABVIEW

WIN-911

WIN-911’s partner product ALERT is a key element in the Supervisory Control and Data Acquisition (SCADA) system “FabView” from Air Liquide. Air Liquide is the second largest supplier of industrial gasses in the world. This SCADA alarm notification system is specifically designed to monitor, among other things, the distribution of gas in a semiconductor manufacturing plant located in Dresden Germany. Like most operations of its type, this facility can’t afford much downtime in its distribution facility. If ALERT detects a leak in a pipeline, the system evaluates how severe the leak is and transfers the data back to the central site or home office. Once the information is back in the main office, the SCADA alert system then transcribes the data into understandable messages to which employees can respond appropriately.

|

|

Buenos Aires: pioneering future-proof connected lighting

SAP

Buenos Aires, the largest city in Argentina, is constantly striving to become more sustainable and more welcoming. The constantly growing population, however, means increasing energy consumption and CO2 emissions, resulting in increasing energy costs and light pollution levels. The city required quality street lighting that would offer impeccable service in order to give its citizens a better place to live. To address these issues, Buenos Aires is implementing innovative solutions that are environmentally sustainable and cost-effective, and that can meet future demands of city life.

|

|

COPA-DATA

WIBU-SYSTEMS

From as early as 1991 COPA-DATA realized a need to find a long-term solution for copy protection – one that encompassed its corporate philosophy of openness and flexibility. Requirements included compatibility with Windows and a trouble-free experience for the customer, who should be able to transfer the key to new or modified equipment, and who is supported with the difficulties that can be encountered in an industrial environment – such as network connections being unavailable or defective.

|

|

Online Calculator Helps Haulers Increase Container Efficiency

Compology

As the waste industry continues to evolve and focus on more efficient and effective methods of tracking and deploying containers and other assets, were excited to be able to offer a solution for our customers.

|

|

Refrigeration System Monitoring - Condis Supermarkets

SmartDataSystem

The CONDIS supermarket chain needed to control reliably that its industrial refrigeration machines were operating correctly. At the same time the solution had to allow for manual testing of the level of refrigerant in the gas circuit when required, from the platform itself. This way they can act quickly in response to an alarm that the system itself should be capable of generating.

|