Case Studies.

Our Case Study database tracks 18,926 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,157)

- (2,048)

- (1,256)

- (926)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,460)

- (1,423)

- View all 42 Industries

- (5,781)

- (4,113)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,391)

- (2,981)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,926 case studies

|

Sensor Synergy Case Study

Lantronix

Whether sensors are stand-alone, connected to PLCs, interfaced to PCs or tied directly to networks, these devices can be found in a multitude of electronics that affect daily life – from washing machines to windshield wiper blades. Although there are a number of ways to add sensor data to a system, designers and users want to keep the sensor-to-system interface process as easy as possible, and, in many cases, users want this information to be accessible via the Internet.In recent years, the IEEE’s (Institute of Electrical and Electronics Engineering) approval of multiple standards, coupled with the increase of factory automation suppliers differentiating themselves by developing different communications protocols, has resulted in over 50 different hardware and software interface protocols. What initially was an opportunity for factory automation suppliers to provide enhanced new features to their customers has become a challenge for sensor manufacturers. It is increasingly difficult to develop sensor solutions that will interface with all applicable protocols. To help alleviate this problem, smart sensor technology pioneer, Sensor Synergy, developed a near-universal sensor-to-Internet solution utilizing Lantronix Device Networking technologies.

|

|

No More Searching for Software

AUVESY-MDT

Tasks such as manual documentation and the fact that new software and hardware is constantly being integrated to the automation network makes the lives of maintenance staff difficult.

|

|

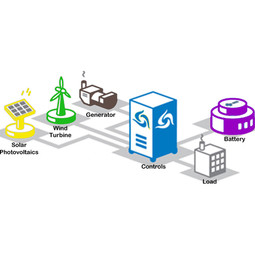

Enabling Next Generation Demand Response Based Power Distribution

Zenodys

There are many sources of electricity available nowadays. In addition to a number of Utility distributors, there is also sun, wind, various co-generation options, etc. Power can also be stored in batteries, facilities or cars. However each of those sources has it’s specifics – the sun doesn’t always shine and wind doesn’t always blow, a battery can get empty… Utility grid is always available, however, power from the grid may be expensive. The challenge that we face next is – how to use those power sources to get the most of them and to justify the investment.

|

|

AWS Migration

ZIN Technologies

Due to its ever increasing customers and connections Wyless required more scalability and efficiency but definitely at a cheaper cost. Usage records & calculations for more than 2 million connections does not reside in gigabyte of space, it requires terabytes of space. Where connectivity is the key to your success or failure in business, you don’t want your machines to be responsible for slow response. Wyless had all of its servers managed at another hosting. Ex-Hosting became non-scalable to support the ever-expanding needs of expansion Wyless required. But moving instance from Ex-hosting was the biggest challenge. Wyless had issues of stability, network availability, scalability & OS. Resulting in not able to scale up the resources like Disk, CPU and Ram without incurring downtime.

|

|

High Consequence Area Mapping Case Study

Federal law requires pipeline operators to monitor areas where large numbers of people reside or gather within close proximity to their pipelines. These high consequence areas (HCAs) are classified based on nearby structures, population density, and business use. HCA designations impact the pipe’s maximum allowable operating pressure (MAOP), size, and inspection requirements.

|

|

Revolutionary Care When and Where it is needed

Cisco

VITAS sees mobile technology as the key to better connecting patients and caregivers. “Mobile technology will allow us to communicate information and route caregivers quickly and efficiently,” says Patrick Hale, senior vice-president and CIO at VITAS. “But before attempting revolutionary work, we needed to lay down the infrastructure.”Due to fast growth, the company lacked a strong, consolidated network. By standardizing on Cisco network and communication solutions, VITAS gains the stability and visibility that it needs to introduce new applications that bring together patients, families, and top-quality healthcare services.

|

|

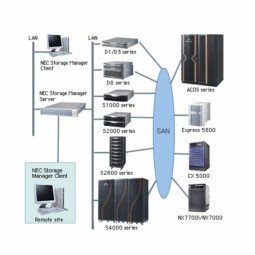

Dynamic IT Infrastructure Re-energizes Power Catalyst

NEC

Power Catalyst needed a solution that can support massive amounts of mission-critical data with no disruption for customers. Antiquated system wasn’t scalable and couldn’t support disaster recovery and could not deploy applications on a service basis with a quick turnaround.

|

|

Internet of Things Enables Smarter Oilfield Operations

Cognizant

Lower oil prices compel oilfield operators to increase efficiency. The client, a leading oilfield services provider, sought to significantly reduce the costs of pumping oil. The client owns and operates tens of thousands of electric submersible pumps (ESPs) for its global oil-and-gas customers.

|

|

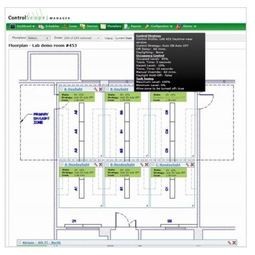

Tacoma Power Reduces Cost and Risk with HMI and SCADA Virtualization

GE Digital (GE)

Tacoma Power, located in Tacoma, WA, serves 160,000 electric utility customers with nine hydro facilities on four rivers. The company’s generation automation team, consisting of three engineers and one engineering technician, is responsible for the integration, modernization. With a small staff responsible for overseeing a number of different environments, the company was looking to implement its HMI/SCADA system in a virtual environment for automation and control in order to optimize operations and reduce costs.

|

|

Point Defiance Zoo & Aquarium Uses IBM Big Data Analytics to Better Engage the Millennial Visitor

IBM

On a daily basis, millions of data records are generated on visitor exhibit and special event preferences and participation in conservation initiatives. Significant visitor feedback is also generated on social channels, such as Facebook, which reveal visitor likes and dislikes and other feedback on overall zoo operations. The zoo needed a lens to focus on the actionable insights that emerge from this massive amount of information.

|

|

Improve Turlock's Water Communication Module

Itron

The City of Turlock has a population of more than 70,000 across a 17-square-mile service territory. The City of Turlock recognized changing water conditions and the need to take action to address impacts from California's drought to ensure future availability of water for residents. The city was interested in automating its meter reading and leak detection processes in support of conservation measures.

|

|

Illuminate the World of Advertising with Outdoor Link

KORE Wireless

Ensure lights are effectively utilized by advertising billboards to increase visibility, revenue and reduce utility costs, while offering multiple connectivity options to customers globally.

|

|

Automating Operations for Fleet Management

Certified Tracking Solutions (CTS) is using on the Internet of Things (IoT) to deliver industry-leading fleet management solutions to both commercial fleet operators and individual consumers. With tens of thousands of connected devices in the field, CTS relies on the Cisco Jasper platform to automate device management and provide customers with real-time intelligence on their devices’ performance and connectivity status.

|

|

IT security for critical infrastructure with versiondog

AUVESY-MDT

Flood prevention and sewerage are highly mechanised and automated services that utilise the latest high-performance computerised controllers and IT networks. For a growing number of public water authorities, the versiondog data management system from AUVESY has significantly improved the process of keeping track of the associated data. Although the primary purpose of versiondog is usually to provide change and data management, it is also helping German water authorities fulfil the requirements of the country's IT Security Act 2015, especially with regard to ICS systems.

|

|

IT Simplification to Improve the Healthcare Computing Environment

IBM

Increasingly sophisticated malware attacks can leave healthcare providers in a vulnerable position as they confront the critical need to improve security while also keeping IT costs under control. Concord Hospital has worked hard to cultivate a reputation for clinical and patient service excellence.As an example of its progressive approach to automating health service delivery, Hospitals & Health Networks magazine has named Concord one of the United States’ “Most Wired Hospitals” for several consecutive years. In order to maintain this level of operational excellence, Concord Hospital needed a solution to save time and resources while also improving results for software licensing, patch management, asset inventory and security configuration.

|

|

Increased Range and Flexibility for Custodia Systems Customers

Vodafone

Custodia Systems is a security consultancy based in the UK. It was founded in 2005 by Peter Thompson, a former Goldman Sachs technology and engineering lead, with start up capital of £4,000 (approximately €4,800). It is now the global distributor of Appello tracking devices and its products currently protect £150 million (€180 million) of construction machinery in the UK.The Appello device is a small, portable unit (no bigger than a smartphone) with a battery life of up to two years. It has no external wiring and cannot be located by scanning devices used by professional thieves like GPS (Global Positioning System) units.The device is hidden, for example among the engineering of a piece of plant machinery and sends out a regular signal to mark its present location. Worldwide, Custodia Systems claims 80% of stolen equipment is recovered and back with its owners within eight hours.To ensure consumer confidence and provide a competitive advantage, Custodia Systems needed a fail-safe communications infrastructure that needed to be international, reliable and as accurate as possible. In addition, to support the launch of the AppelloGEO – a new product that can be used globally – Custodia Systems needed a global platform and fixed price international tariffs.

|

|

Aruba Cuts the Core with Microsoft Lync

Aruba Networks

Aruba's IT team purchased a telephony system which is going end-of-life and this would become a bottleneck to growth. While they began investigating modern PBX systems, they were also considering put their own Wi-Fi infrastructure to work by adopting a Unified Communications and Collaboration solution.

|

|

Compression Facility Industrial Asset Monitoring Solution

Veros Systems

After spending millions on an enhanced oil recovery (EOR) infrastructure, including CO2, compressors, pipelines, injection wellheads, and fluid separators, Chaparral began to see its long-term investment pay off as oil production increased. However, when a CO2 compressor fails, CO2 volumes to the pipeline plummet by 50% or more. The operator needed predictive intelligence to prevent such an event.

|

|

Improving Energy Efficiency at UC Santa Cruz

Daintree Networks (GE Current)

The UC Santa Cruz campus building were costly to keep illuminated at current levels. Daintree Networks attempted to reduce costs by retrofitting the entire campus building, and address limitations in the existing infrastructure. For example, as part of the retrofit, the team also considered the illumination levels and found that the levels were significantly higher than industry recommendations, a situation all too common in campus buildings.

|

|

CTS Relies on Jasper to gain control, increase visibility and save time

Built on the principles of excellence, quality and integrity, the company strives to provide superior service to their customers, and with tens of thousands of devices out in the field, CTS needed a solution to effectively control and manage all devices from a central command center. In other words, they needed a single way to activate and deactivate devices, manage rate plan changes and diagnose problems.

|

|

AUTOMATED DAIRY SYSTEM MONITORING WITH WIN-911 PRO ALARM NOTIFICATION SOFTWARE

WIN-911

For automated dairy systems, maintaining precise environmental conditions is essential; the products (cheeses, milk, butter, ice cream, etc.) are temperature sensitive. Whether during the high-heat phases of bacteria removal and pasteurization or the refrigeration of finished products, a change in temperature can render an entire batch unusable.

|

|

A Customized Cloud Framework Guarantees Vehicle's Mission and Health

Cognizant

A large U.S. heavy equipment manufacturer and logistics company sell its vehicles to dealers who, in turn, rent or sell them to individual customers. An antiquated, on-premises data center made maintaining and managing its 400,000 pieces of heavy equipment a challenge.This outdated environment also made it difficult to scale its vehicle monitoring capabilities, assess vehicle health proactively and capture analytics for insights into performance across the company. With its legacy data center at capacity and the high licensing fees associated with available marketplace solutions, the manufacturer needed a partner to help transform its business operations.

|

|

Robot-supported ultrasonic defect testing and quality control

ArtiMinds Robotics GmbH

Ultrasonic testing is a widely used non-destructive test method to check cast parts for invisible defects such as blowholes, pores or cracks. Since the acoustic properties of the material change if those casting defects are present, the ultrasonic sound pulse is reflected and sent back to the test head.Especially if components have complex geometries, ultrasonic testing is often carried out manually. By automating the process with the help of robots, test costs and test time can be reduced and measurements made reproducible.

|

|

Smart Surveillance

Aikaan Labs

-Managing large scale fleet of remotely located Cameras and IoT Gateways turns out to be operational expensive job.-Upgradation of AI/ML applications running on the Cameras.-Application Orchestration and management becomes challenging for AI and ML applications running across the solution.-Frequent failures require truck rolls.

|

|

Energy Smart Generation by Unatec using Carriots

Energy generation and management, when not optimized, severely damages the results. If costs are not closely controlled or the production is not predicted accurately, profit can be dramatically diminished or even lead to losses. It is therefore mandatory for energy producers to optimize the management to maximize profitability.

|

|

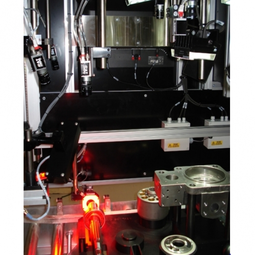

Automated Inspection of Axial Piston Motors

Industrial Vision Systems

Earth moving machines require an immense energy source to provide the power they need for use within civil engineering works. ‘Hydraulic Motors’ allow this power to be applied to enable the machines movement and in addition ‘Control Valves’ also provide the operator with the precise feel and control required to undertake the necessary tasks needed for such machines, including trenching, rock breaking and demolition. These same motors are also used in cranes, wheel loaders and general construction equipment. Though not a new product, the designs of such motors and control valves have been around a few decades, the overall method for manufacture has changed rapidly over the last few years to take account of the need for more modular designs, manufacture and just-in-time manufacturing. Kawasaki Precision Machinery (UK) Ltd based in Plymouth, UK is one of the leading manufacturers of such motors and pumps. They approached Industrial Vision Systems Ltd to come up with a solution to provide automated inspection of such pumps for their semi-automated assembly process. The pumps requiring inspection are at a sub-assembly stage when they are due for the inspection process to take place. Due to the highly modular nature of the construction each part of the pump can have many different derivatives which overall have a different effect on the pump in industrial use. It is therefore critical for the manufacturing process to check all components are the correct type and number for the construction of the pump to begin. Once built it is difficult and costly to rework such units if a fault is detected later in the manufacturing process, therefore automated visual inspection is critical for the success in building quality motors and pumps.

|

|

Increasing Asset Health & Uptime: Chiller Connect

SmartLog

Companies are facing greater challenges than ever before when it comes to making sure their cooling equipment operates at maximum efficiency. One of the challenges is the need to understand how equipment is performing to optimize their use, their health and to anticipate issues and failures. Having an HVAC service engineer who continuously monitors the chiller is unrealistic.

|

|

Industrial Automation

WolkAbout

Ready2Wash needed a partner who can connect a diverse set of machines, systems, and sensors, many of which communicate on different protocols, onto a single platform and make them visible and controllable. Furthermore, the amount of data, data types, and their applications were so vast, that the solution handling it needed to be scalable and flexible.

|

|

Best Buy Slashes App Development Time And Resources With Xively (GCP App)

Xively (Google)

Best Buy wanted to quickly develop and deploy apps to achieve business goals. Also, create apps that are scalable and low-maintenance.

|

|

Reducing Operating Costs And Improving Safety

To ensure safe operation of the nuclear plant, the Institute of Nuclear Power Operations sets the performance objectives and defines the criteria (PO&C) to meet those objectives. The plant personnel manually compare each line item in the CAP report against the PO&C to evaluate the seriousness of the event. A spilled cup of coffee in the wrong place might not be too serious, while a critical pump leaking that has the potential to shut down the plant is another matter entirely. This manual process of classifying the seriousness of each item in a CAP report lies at the heart of the continuous effort to improve the safety and operation of the nuclear power plant, but requires significant time and resources. Our client needed a way to automate the classification process to increase its efficiency and to extract information from years of reported events to better understand their causes and anticipate possible adverse events.

|