Case Studies.

Our Case Study database tracks 18,926 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,157)

- (2,048)

- (1,256)

- (926)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,460)

- (1,423)

- View all 42 Industries

- (5,781)

- (4,113)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,391)

- (2,981)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,926 case studies

|

Predictive maintenance in Schneider Electric

Senseye

Schneider Electric Le Vaudreuil factory in France is recognized by the World Economic Forum as one of the world’s top nine most advanced “lighthouse” sites, applying Fourth Industrial Revolution technologies at large scale. It was experiencing machine-health and unplanned downtime issues on a critical machine within their manufacturing process. They were looking for a solution that could easily leverage existing machine data feeds, be used by machine operators without requiring complex setup or extensive training, and with a fast return on investment.

|

|

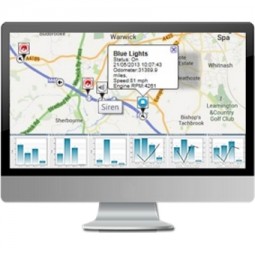

In-Car Cleverness Provides Innovative 'End-To-End' Telemetry Solutions

Aeris

In-car Cleverness provides vehicle telemetry services for fleet management, car rental companies and prestige Dealership Groups. It delivers an innovative ‘end to end’ solution that enables these companies to enhance customer engagement and improve profitability by continually analyzing data from the car. This data can then provide a range of different solutions depending on the customers’ needs. For instance, In-car Cleverness can offer insights into a person’s driving habits and this information can be used to help manage fuel consumption and lower the impact of wear and tear. Alternatively, it can send an alert as soon as a person is involved in a crash. It can also be used to rapidly send data to rental operators or other commercial fleets following a crash, enabling the pinpointing of probable cause and extent of any damage. The company aims to offer its customers, which are made up of businesses in the UK, Ireland, and the rest of Europe, a reliable solution that provides seamless feedback, full visibility and consistent coverage, no matter where in the world the cars are being driven. Telematics has evolved. In-car Cleverness realizes that the focus is now on understanding what the car can tell you. It has pushed beyond simple tracking and fuel consumption data offered by most telematics providers, and can accurately, cost-effectively and remotely extract and present data from the engine management systems of a vehicle in an intuitive format. It can then process and analyze that data to deliver tangible operational and, more importantly, financial benefits to its customers. In-car Cleverness’ solutions continue to expand around the world, demanding a flexible and reliable data network solution for customers, wherever they might be, and whatever systems they might use. It requires a reliable global mobile network that provides consistent connectivity worldwide, without the burden of costly roaming charges.

|

|

Microlise Drives Vehicle Telemetry Solutions

Vodafone

Microlise is among only a handful of players in the Transport Management Systems space that offer a one stop solution and service capability. Its investment in research and development needs to be underpinned by a robust, global connectivity platform, enabling the reliable transmission of data from vehicles to customers.

|

|

IIC Condition Monitoring & Predictive Maintenance Testbed

NI

The current state of condition monitoring requires manual measurements that are compounded with aging equipment and the retirement of knowledgeable personnel.

|

|

Dignity Health Wayfinding

Phunware

Dignity Health needed a mobile solution for wayfinding and patient experience that would reflect its corporate branding while serving the unique needs of each facility

|

|

Porsche Announces Augmented Reality at Scale, Powered by Atheer

Atheer

The usual practice for car repairs at a Porsche car dealership is to have a factory representative or regional engineer visit to help diagnose the problem, and sometimes a faulty assembly is shipped back to company HQ for damage analysis. All that costs time and money for customers and dealers alike.

|

|

Scalable Predictive Maintenance in Nissan

Senseye

With an abundance of data and insufficient skilled resources to perform analysis, Nissan were keen to expand the benefits of using data to influence maintenance. It decided to embark on a Condition Based maintenance programme to reduce production downtime by up to 50% across thousands of diverse assets. It was attracted to Senseye by its strong prognostics offering underpinned by machine learning.

|

|

The Data Tsunami for AGL Energy

SAP

AGL Energy, one of Australia’s largest power retailers, is replacing its electromechanical meters with interactive smart meters in 2.2 million homes and 300,000 businesses throughout the state of Victoria, including its capital, Melbourne. This is nearly a 4,320-fold increase in daily data processing for electricity providers. It’s also the start of a “data tsunami,” swelling up from these 2.5 million smart meters and flowing into AGL Energy’s billing and operations systems.AGL’s Business Requirements- For wholesale energy: Improved settlement reporting- For merchant energy portfolio management: Better load forecasting, accuracy and data analytics / segmentation with better reporting- For analytics: Better forecasting and reporting

|

|

GE Healthcare Delivers Core Customer Solutions on the Microsoft Cloud

Microsoft

Two of the company’s businesses—GE Healthcare IT and GE Healthcare Global Services—sought to provide customers with more flexible, yet secure cloud solutions. GE Healthcare IT software and services for Integrated Care create actionable insight across the healthcare system and the care pathway, enabling better clinical and financial outcomes. Healthcare Global Services help health systems manage their operational resources to deliver high quality care safely, efficiently, and affordably. Both business groups knew that while healthcare providers worldwide need better insight and control over data to both improve efficiency and improve clinical care, they must also protect patient information and meet increasingly challenging regulatory requirements Moreover, the company sought to meet its goals without investing additional time and money in on-premises infrastructure.In the United States, GE Healthcare sought to simplify Meaningful Use (MU) reporting to help facilitate the MU attestation required to qualify for incentives from programs established through the Health Information Technology for Economic and Clinical Health Act (HITECH Act). Customers in other countries also have compliance needs, and GE Healthcare wanted a solution that it could easily adapt to a wide range of privacy and security requirements.

|

|

A Smarter Brain for Your Train…

Intel

Have you ever felt overloaded by too much sensory input? The results can be problematic, even risky if you’re driving at the time. The same holds true for trains, ships, oil rigs, and many other industrial assets. The data processing challenges on these complex machines are growing rapidly as the number of sensors increases; yet so are the opportunities to transform operations by using all the available data effectively. A modern locomotive, for example, has as many as 200 sensors generating more than a billion data points per second.

|

|

Ensures Cold Milk in Your Supermarket

Secomea

As of 2014, AK-Centralen has over 1,500 Danish supermarkets equipped, and utilizes 16 operators, and is open 24 hours a day, 365 days a year. AK-Centralen needed the ability to monitor the cooling alarms from around the country, 24 hours a day, 365 days a year. Each and every time the door to a milk cooler or a freezer does not close properly, an alarm goes off on a computer screen in a control building in southwestern Odense. This type of alarm will go off approximately 140,000 times per year, equating to roughly 400 alarms in a 24-hour period. Should an alarm go off, then there is only a limited amount of time to act before dairy products or frozen pizza must be disposed of, and this type of waste can quickly start to cost a supermarket a great deal of money.

|

|

Fresh Solutions for Fresh Produce

SAP

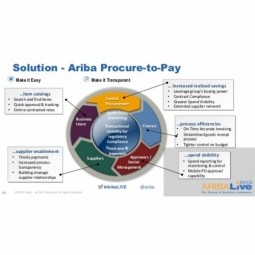

Dole processes 48,000 purchase orders each year from farmers across several countries and regions. In order to shorten the PO process, Dole needed to centralize all data and standardize and automate the tools, information, and practices used to manage procurement processes across the region, to save precious time and money. The company looked to SAP to streamline the entire procure-to-pay process.

|

|

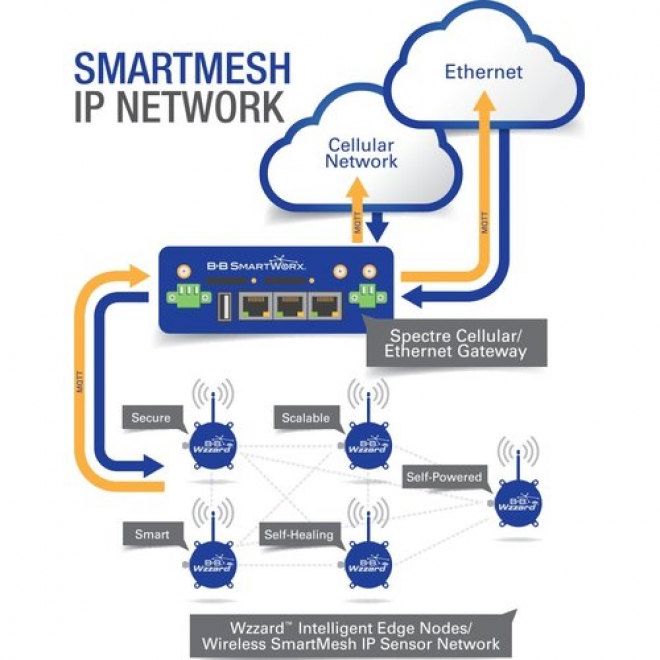

Condition Based Monitoring for Industrial Systems

Advantech B+B SmartWorx

A large construction aggregate plant operates 10 high horsepower Secondary Crusher Drive Motors and associated conveyor belts, producing 600 tons of product per hour. All heavy equipment requires maintenance, but the aggregate producer’s costs were greatly magnified any time that the necessary maintenance was unplanned and unscheduled. The product must be supplied to the customers on a tight time schedule to fulfill contracts, avoid penalties, and prevent the loss of future business. Furthermore, a sudden failure in one of the drive motors would cause rock to pile up in unwanted locations, extending the downtime and increasing the costs.Clearly, preventative maintenance was preferable to unexpected failures. So, twice each year, the company brought in an outside vendor to attach sensors to the motors, do vibration studies, measure bearing temperatures and attempt to assess the health of the motors. But that wasn’t enough. Unexpected breakdowns continued to occur. The aggregate producer decided to upgrade to a Condition Based Monitoring (CBM) sensor system that could continually monitor the motors in real time, apply data analytics to detect changes in motor behavior before they developed into major problems, and alert maintenance staff via email or text, anywhere they happened to be.A wired sensor network would have been cost prohibitive. An aggregate plant has numerous heavy vehicles moving around, so any cabling would have to be protected. But the plant covers 400 acres, and the cable would have to be trenched to numerous locations. Cable wasn’t going to work. The aggregate producer needed a wireless solution.

|

|

Eseye puts Airmax on Target for 15% Cost Reduction

Eseye

Airmax wanted a provider who would take complete responsibility of their connectivity, without restricting them to a single network. They wanted a simple solution along with assurance that they were getting the best value for money, customer care and network flexibility.

|

|

Ecolibrium Energy Helps Reduce India's Energy Wastage

Vodafone

Ecolibrium’s SmartSense solution connects sensors to energy infrastructure within a factory. It then sends energy consumption data, temperature and environmental data to a central platform. This data can be sent each minute, providing a near real-time view of energy consumption and analytics on where problems occur, what they are and recommendations on how to fix them. To work, each device needs robust connectivity that is simple to manage and consistent in pricing.

|

|

Reducing the Rate of Readmissions

ThingWorx

The client had limited or inefficient integration of its data sources, which made it difficult to see patients through a longitudinal lens. The client was, however, uniquely positioned to leverage the expansive patient data contained within its network of care, and set out to do so in 2012. Specifically, they wanted to improve the outcomes of patients with Ischemic Heart Disease (IHD) through improved care management with goals of reducing readmission rates, better managing patient cholesterol levels, and better managing patient blood pressure. Specifically, the regional healthcare provider was interested in implementing a machine learning platform, that quickly automates complex analytical processes and integrates powerful information into existing applications and portals.

|

|

ABB Increases Productivity and Reduces Operational Costs

ABB relies on Control Center to monitor connections to its customers' industrial robots for potential problems. As soon as conditions change, ABB engineers want to know about it so that they can act on it. Engineers wanted a solution so that they can anticipate problems by constantly analyzing the information that they receive from the devices. They have developed a set of predictive KPIs, which they share with their customers to help them decide if their equipment requires maintenance.

|

|

Proactive Maintenance Saving Millions of Dollars

One of the world’s largest exploration and production companies was operating as leanly as possible given the prolonged slump in oil prices. As such, an operational parameter wasn’t effectively monitored and equipment failure went unnoticed in the machines.

|

|

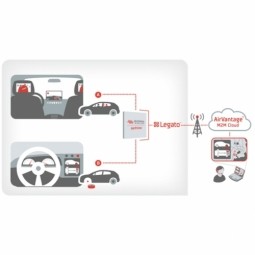

Keeping Electric Vehicles Running With AirVantage Smart Automation

Sierra Wireless

Schneider Electric develops charging terminals for Electric Vehicle Charging Stations (EVCS) throughout the test territory. In order to meet the timeline required for the project, as well as include the remote monitoring and control necessary to manage charging terminals dispersed through 51 towns and five counties, Schneider Electric turned to Sierra Wireless to assist in a quick development of a service and maintenance connected electric charging terminal.

|

|

PC-based PAC solution for material handling AGV optimization

Advantech

Widely used across many industries, Automated Guided Vehicles (AGV) have been scooting around factory floors for decades. Thanks to evolving technologies like sensors, wireless networks and automatic control technologies, their guidance methods and physical dimensions continue to evolve and now small lightweight trackless AGV are being rolled out. An American AGV System Integrator (SI) was designing a Laser Guided Vehicle (LGV) for a material handling system in an automotive assembly plant. Since the plant’s existing AGV system used an expensive PLC-based control system there weren’t enough functions to meet the new control requirements, the company decided to upgrade and shift to a compact PC-based PAC control system ideal for the new compact vehicle design, capable of integrating with upper management systems using a single software application to replace the original two software applications.

|

|

Work with Asparagus Farmers on IoT Solution

Deepfield Robotics (Bosch)

The quality of asparagus depends heavily on the temperature of the ground in which it’s grown. To control the temperature, farmers use a two-sided sheet of foil: the black side draws in sunlight to increase the heat of the asparagus bed, and the white side reflects light to cool the bed down. In order to make the right “black or white” decision, the farmer needs to measure the temperature of every field at least once each evening.

|

|

Automated Slab Tracking at ThyssenKrupp

S+P Samson

Steel slabs usually weigh between 20 to 40 tons each. After production, the surface is scaly and rusty. Outdoor storage and sea shipment expose the slabs to rough conditions. Loading ocean vessels is time consuming and total cost can easily exceed a few hundred thousand USD.RFID technology offers many benefits. RFID transponders are small, store the identity of the labelled product and enable readingout this data via antennas from a distance of several metres. However, there are special requirements for the use of RFID in thesteel sector. Firstly, the radio waves of the RFID readers are reflected by metal which creates major problems for reading out.And secondly, they must be attached securely as the heavy slabs weigh tons and can rub against each other during the transporton ships and trains, causing the labels to become detached or to be destroyed.

|

|

Advanced Pharmaceutical Manufacturing

Decisyon

Direct communication between departments, plant floor operations, and management is an ongoing challenge due to lack of real-time collaboration around actual data to help improve process flow and on-time order delivery.

|

|

Honeywell Helps Carvajal Pulp and Paper Drive Smart Operations

Honeywell

Carvajal Pulp and Paper was challenged to lower its Manufacturing Costs to become more competitive. This reflected in the needs to gain more control over energy costs, chemical costs, and production losses.

|

|

Machine Condition Monitoring for a Distribution Center

Advantech B+B SmartWorx

A distribution center used a conveyor belt systems to transport a wide variety of products to appropriate locations. When all went well, products were delivered, stored and shipped back out with a minimum of trouble. But a breakdown in any of the motors running the conveyor belts could interfere with operations and cause unacceptable shipping delays. The distribution center decided to use remote monitoring and decision analytics to predict where and when, preventative maintenance could keep small problems from ballooning into major disruptions.

|

|

Intelligent Telematics uses IoT to improve fleet safety and cut insurance costs

“IoT plays a critical role in keeping costs down. If a third party takes hold of a claim, costs spiral out of control,” says Sam Footer, Head of International Business and Strategic Development at Intelligent Telematics. Typically, corporate trucks and taxis are blamed for crashes involving consumer cars, prompting companies to often settle claims to avoid going to court.

|

|

Connected Technology Evolves Farmers' Operations

Digi

Customers of Nebraska Engineering Company (NECO) needed the capability to know the grain dryer’s status at all times while couldn’t afford to have someone at the dryer all the time to ensure it is doing what it is supposed to do.

|

|

Electronic Prescribing of Controlled Substances Offers Security

Pharmacists often make a mistake in filling the prescription because of a poorly-written script. These mistakes can lead to dangerous misdosing or drug interactions with other medicines that have an adverse effect on the quality of patient care. Exostar recognized the huge burden for health IT vendors to enable Electronic Prescribing of Controlled Substances (EPCS) for their providers.

|

|

Remote Monitoring

Advanticsys

Kaunas Energija's Heat and Power Plants were distributed across the country, including in places lacking an internet connection. This made supervision and maintenance difficult and expensive.

|

|

Controlling and Monitoring Microgrids

NI

Microgrid topologies offer several advantages over large traditional grids including increased resiliency and easier integration of distributed renewables. However, some challenges such as maintaining scalability and interoperability between diffferent vendors and connectivity protocol standards are challenges that have to be overcome in order to reap the benefits of such a system.

|