Aerospace & Defense Case Study Airbus

- Analytics & Modeling - Digital Twin / Simulation

- Aerospace

- Product Research & Development

- Remote Collaboration

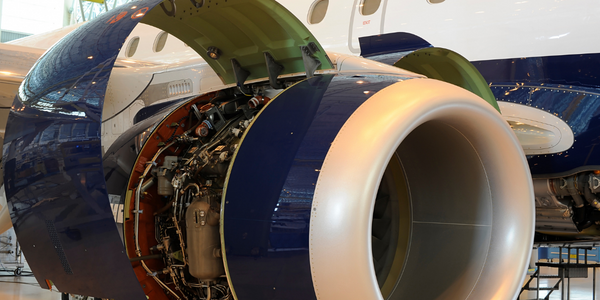

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Airbus uses Dassault Systemes' 3DEXPERIENCE applications for design, simulation and manufacturing on a single platform, where employees and suppliers collaborate in real-time on a unique digital mockup. Airbus federated their development platforms under one umbrella ENOVIA and provided Airbus employees and the extended enterprise with access to this unique data reference.

Related Case Studies.