Aircraft Predictive Maintenance and Workflow Optimization

- Analytics & Modeling - Machine Learning

- Analytics & Modeling - Predictive Analytics

- Aerospace

- Maintenance

- Predictive Maintenance

- Root Cause Analysis & Diagnosis

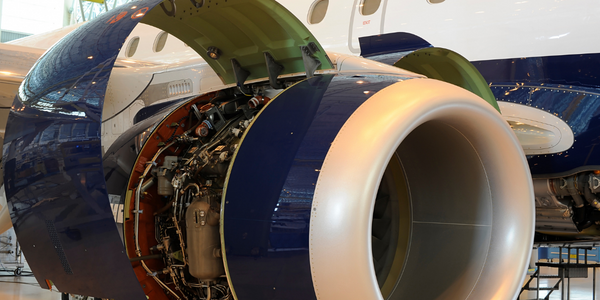

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

SparkPredict leverages cutting edge machine learning techniques to build machine-scale pattern recognition models to monitor mechanical systems within an aircraft, and predict failure. The cognitive nature of these algorithms means that SparkPredict can be deployed to an aircraft system in any location and the insights will adapt to the unique characteristics of that particular plane. In addition, SparkPredict can integrate with other systems such as diagnostic databases, maintenance records, and personnel records to help classify fault codes, recommend the right personnel, and schedule maintenance in an optimal manner. This will reduce the time an aircraft has to spend on the ground.

Related Case Studies.