Download PDF

Megayacht Builder Leverages Simulation Software for Enhanced Design Flexibility

Technology Category

- Robots - Parallel Robots

- Sensors - Haptic Sensors

Applicable Industries

- Marine & Shipping

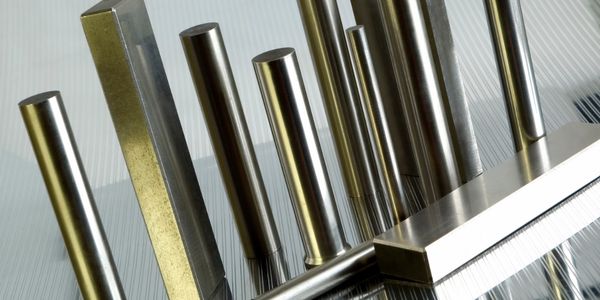

- Metals

Applicable Functions

- Product Research & Development

Use Cases

- Predictive Maintenance

- Structural Health Monitoring

The Challenge

Delta Marine Industries Inc., a leading megayacht builder, faced a significant challenge in meeting the high customization demands of their clients. The company's clientele, purchasers of 100-foot plus megayachts, expected the ability to highly customize the interior design of their yachts. This demand for customization, particularly the freedom to place walls or partitions wherever desired, created structural design challenges by increasing the complexity of the load paths. The non-alignment of pillars made it difficult to determine how loads would distribute across various structural elements. Traditional design methods were inadequate due to the highly nonlinear and difficult to discretize load paths. Furthermore, Delta Marine was tasked with building a megayacht that not only had a luxurious interior and high cruising speed but also optimized weight and structural elements for strength and vibration resistance.

About The Customer

Delta Marine Industries Inc. is an award-winning yacht builder and one of the world's leading builders of megayachts. The company boasts a team of naval architects, marine engineers, and skilled workers with years of experience in specialized fields. Delta Marine expertly combines old-world craftsmanship with the latest technology to deliver high-quality, customized yachts to its clients. Their clientele primarily consists of purchasers of 100-foot plus megayachts who expect high levels of customization in the interior design of their yachts.

The Solution

To overcome these challenges, Delta Marine utilized ANSYS Mechanical, a simulation software. The company modeled the yacht's major shapes in Rhinoceros and imported them into ANSYS Mechanical. They used composite shell elements to model the laminate stack and solid elements for scantlings parts cast in resin. This approach allowed them to evaluate global and local stresses, simplifying the design of plating, beams, and pillars. They also used FE reports to detail and defend structural decisions that regulatory rule books could not adequately cover. Additionally, they performed a modal analysis to identify critical modes of vibration and addressed high bending moments by strengthening the hull and decks in areas of high bending. This solution enabled the designers to place walls and partitions wherever they wanted while maintaining strength, keeping the weight to a minimum, preventing vibration, and delivering a high level of performance in a luxury yacht that is aesthetically pleasing.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.

Case Study

Continuous Casting Machines in a Steel Factory

With a very broad range of applications, steel is an important material and has been developed into the most extensive alloy in the engineering world. Since delivering high quality is absolutely crucial for steel plants, ensuring maximum productivity and the best quality production are the keys to competitiveness in the steel industry. Additionally, working conditions in steel factories are not suitable for workers to stay in for long periods of time, so manufactures usually adopt various machines to complete the steel production processes. However, the precision of these machines is often overestimated and the lack of flexibility also makes supervisors unable to adjust operating procedures. A renowned steel factory in Asia planned to improve its Distributed Control System (DCS) of furnaces as well as addressing the problem of insufficient accuracy. However, most well-known international equipment suppliers can not provide a satisfactory solution and local maintenance because the project needed new technologies to more accurately control equipment operations. By implementing Advantech’s automated monitoring and control solution, steel factories can not only improve the manufacturing processes but can also allow users to add additional functions to the existing system so as to make sure the operation runs at high efficiency.

Case Study

Automated Predicitive Analytics For Steel/Metals Industry

Asset to be monitored: Wire Compactor that produces Steel RebarCustomer Faced The Following Challenges:Dependent upon machine uptime.Pressure cylinders within the compactor fail to control compression and speed causing problems in binding the coil.Equipment failure occurs in the final stage of production causing the entire line to stop, can you say bottleneck?Critical asset unequipped with sensors to produce data.