Surface Defect Inspection of 3D Line Laser Scanning Auto Tire Radius Pattern

- Analytics & Modeling - Process Analytics

- Sensors - Camera / Video Systems

- Automotive

- Discrete Manufacturing

- Computer Vision

- System Integration

From the pursuit of car ownership to the pursuit of higher quality and safe cars, tires are an important part of car safety.

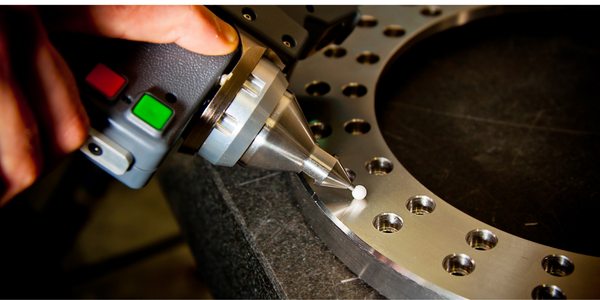

Hardware: 3 sets of laser profile sensors are used, 1 set to detect tread, width, texture depth, wheel radius, 2 sets to detect side surface, to detect obvious wear, such as tire bulge, 3 sets of synchronous sensors measure synchronously to eliminate the influence of tape jitter. Fibre optic and wireless CDMA transmission lines.

- Equipment width error requirements ≤0.5mm;

- Texture depth detection error requirements ≤0.2mm

- Wheel radius detection error requirements ≤0.5mm

- Detection frequency requirements: 1 detection per second

- Set the installation distance of the installed sensor from the tape to 650mm

Software: Through the advantages of operation and maintenance software and big data analysis developed by TUS-INVENT, the application solution realizes real-time collection and reporting of the 3D line laser scanning data of the product, and real-time intelligent alarm according to the background control centre analysis and simulation setting alarm value. It meets the dual real-time push of digital switch signals, alarm information graphics and digital signals, the graphical display, the display of the 3D profile of the tire tread, and the display of measurement elements provide users with high-sensitivity highlights.

Related Case Studies.