下载PDF

Surface Defect Inspection of 3D Line Laser Scanning Auto Tire Radius Pattern

技术

- 分析与建模 - 过程分析

- 传感器 - 相机/视频系统

适用行业

- 汽车

适用功能

- 离散制造

用例

- 计算机视觉

服务

- 系统集成

挑战

从追求汽车保有量到追求更高品质和安全的汽车,轮胎是汽车安全的重要组成部分。

解决方案

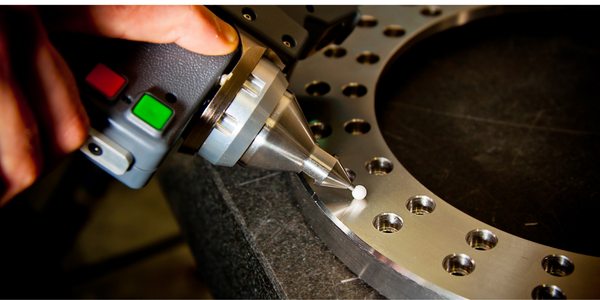

硬件:使用3组激光轮廓传感器,1组检测胎面、宽度、纹理深度、轮径,2组检测侧面,检测明显磨损,如轮胎鼓包,3组同步传感器同步测量消除磁带抖动的影响。光纤和无线 CDMA 传输线。

- 设备宽度误差要求≤0.5mm;

- 纹理深度检测误差要求≤0.2mm

- 轮径检测误差要求≤0.5mm

- 检测频率要求:每秒1次检测

- 将已安装的传感器与胶带的安装距离设置为 650mm

软件:通过启迪自主研发的运维软件和大数据分析优势,应用方案实现对产品3D线激光扫描数据的实时采集和上报,根据数据实时智能报警后台控制中心分析模拟设置报警值。满足数字开关信号、报警信息图形和数字信号双重实时推送,图形显示、胎面3D轮廓显示、测量元素显示,为用户提供高灵敏度亮点。

运营影响

数量效益

相关案例.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

Monitoring of Pressure Pumps in Automotive Industry

A large German/American producer of auto parts uses high-pressure pumps to deburr machined parts as a part of its production and quality check process. They decided to monitor these pumps to make sure they work properly and that they can see any indications leading to a potential failure before it affects their process.