Download PDF

Materialise

Overview

HQ Location

Belgium

Year Founded

1990

Company Type

Private

Revenue

$100m-1b

Employees

1,001 - 10,000

Website

Company Description

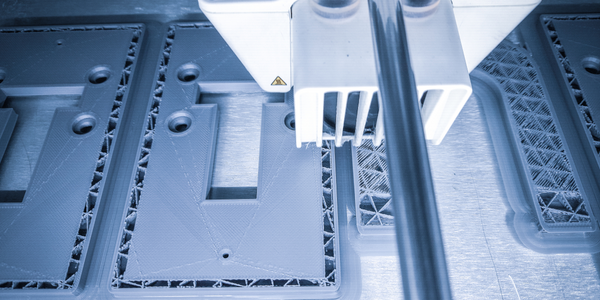

Materialise has been playing an active role in the field of Additive Manufacturing (also known as 3D Printing) since 1990. In addition to having the largest capacity of Additive Manufacturing equipment in Europe, we are also known for our innovative software solutions.

We have used our experience and expertise to create a better and healthier world through our involvement in Additive Manufacturing for industrial and medical applications, and by providing bio-medical and clinical solutions such as medical image processing and surgical simulations. The advantages of Additive Manufacturing have been used by Materialise to develop unique solutions that make a world of difference for our many customers with their prototyping, production, and medical needs. These customers range from large companies in the automotive, consumer electronics, and consumables sectors; to famous hospitals, research institutes, and clinicians; to individual consumers interested in bringing their own unique creations to life through i.materialise or who want to purchase a celebrated .MGX design.

We have used our experience and expertise to create a better and healthier world through our involvement in Additive Manufacturing for industrial and medical applications, and by providing bio-medical and clinical solutions such as medical image processing and surgical simulations. The advantages of Additive Manufacturing have been used by Materialise to develop unique solutions that make a world of difference for our many customers with their prototyping, production, and medical needs. These customers range from large companies in the automotive, consumer electronics, and consumables sectors; to famous hospitals, research institutes, and clinicians; to individual consumers interested in bringing their own unique creations to life through i.materialise or who want to purchase a celebrated .MGX design.

IoT Snapshot

Materialise is a provider of Industrial IoT functional applications, wearables, and other technologies, and also active in the aerospace, automotive, and healthcare and hospitals industries.

Technologies

Use Cases

Industries

Services

Technology Stack

Materialise’s Technology Stack maps Materialise’s participation in the functional applications, wearables, and other IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

Case Study

Hyundai Motors' Production Efficiency Boost with Automation Software

Hyundai Motor Corporation, a world-renowned car manufacturer, was facing challenges in managing their Additive Manufacturing (AM) production. The company had to schedule different build jobs, maintain an overview of all build statuses, and ensure efficient information flow among all stakeholders. Previously, they relied on Excel sheets to manage the RP production status, which required frequent manual updates and dissemination of information. Tracking the number of parts produced, savings, and other operational data required manually generated reports. Machine operators also had to invest significant work hours to manually manage the operating plan for each machine and adjust and communicate the planning as soon as changes occurred.

Case Study

Revamping Automotive Tool Design with Additive Manufacturing

The automotive industry has been facing challenges with the traditional drape forming process, a method used to adhere materials to car interiors. The conventional process uses a metal tool with heating and cooling channels to glue materials like leather onto car interiors. However, the tool, made by milling solid metal blocks, only allows for straight-line drilling of channels, limiting design possibilities. This limitation often leads to long cycle times and inconsistent heating and spreading of the glue, resulting in time and material wastage when the outcome doesn't meet the strict quality standards of the industry. The challenge was to eliminate these issues caused by using conventionally manufactured tools.

Case Study

Personalized Automation: FITme's Journey to Increase Productivity by 346% with 3D Printing

FITme, a Korean-based company specializing in manufacturing implants for facial reconstruction, faced a significant challenge in scaling up their processes for mass personalization. The conventional process of fitting a ready-made silicone implant onto bone structure with manual carving was time-consuming and lacked precision. Surgeons had no tool to analyze patients' scan data and relied solely on photographs. This led to side effects such as bending and movement of the implant, resulting in patient dissatisfaction. The medical tourism industry in Korea was rapidly rising, and FITme had to meet higher demands and reduce lead time. The process of designing custom nasal implants that conformed to the variable shape of patient nasal profiles was a daunting and repetitive task for design engineers. It took up to three months to adequately train new engineers in designing patient implants, which was also expensive.

Similar Suppliers.

Supplier

Altair

Altair is a leading provider of enterprise-class engineering software enabling innovation, reduced development times, and lower costs through the entire product lifecycle from concept design to in-service operation. Our simulation-driven approach to innovation is powered by our integrated suite of software which optimizes design performance across multiple disciplines encompassing structures, motion, fluids, thermal management, electromagnetics, system modeling and embedded systems, while also providing data analytics and true-to-life visualization and rendering.

Supplier

Opentrends

Opentrends provides the most advanced custom software solutions to place companies in the Digital Transformation path, allowing them to achieve innovation advantage and contribute to their growth acceleration.More than 18 years delivering innovative projects of high technological complexity in a wide range of industries, while guaranteeing quality and alignment with our client’s objectives. In fact, over a hundred global companies across various industries have full Trust in our unique ability to design, build, implement, and integrate complex software innovations into their organizations.Let’s excel your digital future today.

Supplier

Dedicated Computing

Dedicated Computing is a global technology company committed to solving the business problems of our customers through the design, development and deployment of innovative technology solutions.We have over 20 years of industry-focused experience in serving customers with imaging, modeling, visualization, and simulation applications. Our expertise ensures our solutions meet the regulatory and compliance, uptime and system availability, and information Assurance requirements that are mission-critical to their applications.