下载PDF

Materialise

概述

公司介绍

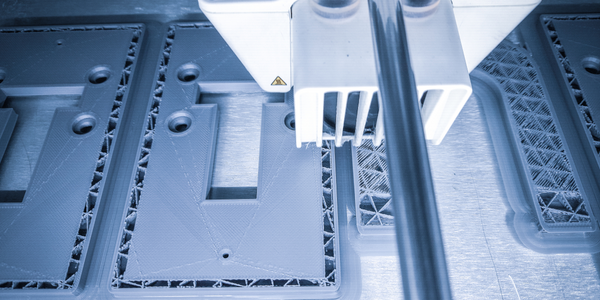

自 1990 年以来,Materialise 一直在增材制造(也称为 3D 打印)领域发挥积极作用。除了拥有欧洲最大的增材制造设备产能外,我们还以创新的软件解决方案而闻名。我们利用我们的经验和专业知识,通过参与工业和医疗应用的增材制造以及提供生物医学和临床解决方案(例如医学图像处理和手术模拟)来创造一个更美好、更健康的世界。 Materialise 已利用增材制造的优势开发独特的解决方案,为我们的众多客户的原型设计、生产和医疗需求带来不同的世界。这些客户包括汽车、消费电子和消耗品领域的大公司;知名医院、科研院所、临床医生;面向有兴趣通过 i.materialise 将自己独特的创作变为现实的个人消费者或想要购买著名的 .MGX 设计的个人消费者。

物联网应用简介

技术栈

Materialise的技术栈描绘了Materialise在功能应用, 可穿戴设备, 和 其他等物联网技术方面的实践。

-

设备层

-

边缘层

-

云层

-

应用层

-

配套技术

技术能力:

无

弱

中等

强

实例探究.

Case Study

Hyundai Motors' Production Efficiency Boost with Automation Software

Hyundai Motor Corporation, a world-renowned car manufacturer, was facing challenges in managing their Additive Manufacturing (AM) production. The company had to schedule different build jobs, maintain an overview of all build statuses, and ensure efficient information flow among all stakeholders. Previously, they relied on Excel sheets to manage the RP production status, which required frequent manual updates and dissemination of information. Tracking the number of parts produced, savings, and other operational data required manually generated reports. Machine operators also had to invest significant work hours to manually manage the operating plan for each machine and adjust and communicate the planning as soon as changes occurred.

Case Study

Revamping Automotive Tool Design with Additive Manufacturing

The automotive industry has been facing challenges with the traditional drape forming process, a method used to adhere materials to car interiors. The conventional process uses a metal tool with heating and cooling channels to glue materials like leather onto car interiors. However, the tool, made by milling solid metal blocks, only allows for straight-line drilling of channels, limiting design possibilities. This limitation often leads to long cycle times and inconsistent heating and spreading of the glue, resulting in time and material wastage when the outcome doesn't meet the strict quality standards of the industry. The challenge was to eliminate these issues caused by using conventionally manufactured tools.

Case Study

Personalized Automation: FITme's Journey to Increase Productivity by 346% with 3D Printing

FITme, a Korean-based company specializing in manufacturing implants for facial reconstruction, faced a significant challenge in scaling up their processes for mass personalization. The conventional process of fitting a ready-made silicone implant onto bone structure with manual carving was time-consuming and lacked precision. Surgeons had no tool to analyze patients' scan data and relied solely on photographs. This led to side effects such as bending and movement of the implant, resulting in patient dissatisfaction. The medical tourism industry in Korea was rapidly rising, and FITme had to meet higher demands and reduce lead time. The process of designing custom nasal implants that conformed to the variable shape of patient nasal profiles was a daunting and repetitive task for design engineers. It took up to three months to adequately train new engineers in designing patient implants, which was also expensive.

同类供应商.

Supplier

Altair

Altair is a leading provider of enterprise-class engineering software enabling innovation, reduced development times, and lower costs through the entire product lifecycle from concept design to in-service operation. Our simulation-driven approach to innovation is powered by our integrated suite of software which optimizes design performance across multiple disciplines encompassing structures, motion, fluids, thermal management, electromagnetics, system modeling and embedded systems, while also providing data analytics and true-to-life visualization and rendering.

Supplier

Opentrends

Opentrends provides the most advanced custom software solutions to place companies in the Digital Transformation path, allowing them to achieve innovation advantage and contribute to their growth acceleration.More than 18 years delivering innovative projects of high technological complexity in a wide range of industries, while guaranteeing quality and alignment with our client’s objectives. In fact, over a hundred global companies across various industries have full Trust in our unique ability to design, build, implement, and integrate complex software innovations into their organizations.Let’s excel your digital future today.

Supplier

Dedicated Computing

Dedicated Computing is a global technology company committed to solving the business problems of our customers through the design, development and deployment of innovative technology solutions.We have over 20 years of industry-focused experience in serving customers with imaging, modeling, visualization, and simulation applications. Our expertise ensures our solutions meet the regulatory and compliance, uptime and system availability, and information Assurance requirements that are mission-critical to their applications.