Download PDF

Nanoprecise Sci Corp

Automated Predictive Maintenance

Overview

HQ Location

Canada

Year Founded

2017

Company Type

Private

Revenue

< $10m

Employees

11 - 50

Website

Company Description

Nanoprecise has created a "patent-pending" solution (hardware + software) that combines physics, material science, and data analytics to diagnose issues with machinery and detects anomalies, characterizes the faulty components and predicts the "Remaining Time to Failure." Since Nanoprecise was founded in Dec 2017, it has customers spanning across Oil & Gas, Mining, Utilities, HVAC & Infrastructure sectors.

IoT Solutions

Nanoprecise's sensor is the first sensor in the world that extracts RPM, vibration, sound, temperature & humidity information, all from one sensor. The software (which is built on AI algorithms that are only limited to research papers until now) analyzes the data from various sensing elements and achieves Anomaly Detection, fault characterization & remaining useful life prediction. This end to end solution can be deployed cost-effectively and can be utilized on any machine in the world in any industry.

Nanoprecise has developed VibrationLF, a Predictive Maintenance solution incorporating wireless sensors based on nanotechnology and sophisticated Machine Learning technology to accurately diagnose faults in rotating equipment and provide a forecast time to replacement, allowing maintenance teams to plan their maintenance activities.

Nanoprecise has developed VibrationLF, a Predictive Maintenance solution incorporating wireless sensors based on nanotechnology and sophisticated Machine Learning technology to accurately diagnose faults in rotating equipment and provide a forecast time to replacement, allowing maintenance teams to plan their maintenance activities.

Key Customers

AltaSteel, Hindustan Zinc, Iffco, BJ

IoT Snapshot

Nanoprecise Sci Corp is a provider of Industrial IoT sensors technologies, and also active in the chemicals, and utilities industries.

Technologies

Use Cases

Industries

Technology Stack

Nanoprecise Sci Corp’s Technology Stack maps Nanoprecise Sci Corp’s participation in the sensors IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

Case Study

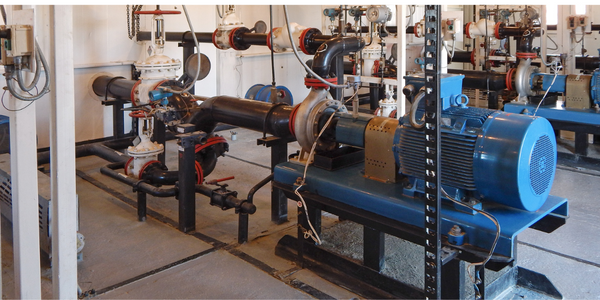

Detecting Cavitation And High Vane Pass Frequency For Pumps

The Condensate Cooling Water (CCW) pump, one of the critical pumps in maintaining steadystate operations, is a horizontal vane pump operating at up to 1650 m3/hr with a discharge pressure of 9 MPa (62 psi) at 986 rpm. Each day this pump is offline costs the plant $250,000 in lost revenue and each failure costs tens of thousands of dollars to execute an unplanned repair. Thus, Larsen & Toubro (L&T) really needed a predictive maintenance solution to detect faults at an early stage and provide a reliable prediction of Remaining Useful Life (RUL)

Case Study

Detection of a Bearing Outer Race Failure on a critical pump saved downtime cost

The process condensate pump, one of the critical pumps in the manufacturing process, has a history of failures every 6 to 12 months. It is a centrifugal pump operating at 3000 rpm with a discharge pressure of 28 MPa (400 psi). Each day this pump is offline, it costs the plant as much as $145,000 in lost production and each failure costs tens of hundreds of dollars to execute an unplanned repair. Nanoprecise Sci Corp was asked to implement a predictive maintenance solution in order to detect faults at an early stage and provide a reliable prediction of Remaining Useful Life (RUL).

Case Study

Automatic monitoring of acoustic emission saves catastrophic failure

Traditional measurement tools are ineffective when it comes to slowly rotating equipment. There are faults like Bearing Failure, Ring Plugging, Gear Tooth Crack and many more which can lead to the shutdown of machines. 1 minute of downtime cost the company $10. RingPluggingis a very common issue which Pinnacle Pellet was facing very frequently due to diverse feed quality into the machines. Product ring plugging can be detected as sound levels increase in specific roller bearings.

Similar Suppliers.

Supplier

Adroit Technologies

Adroit Technologies is a privately held software development company that has been developing award winning real-time software for the industrial automation markets for over 25 years. The principal activities of the company are product development, consulting and solutions development, primarily in the industrial sector. Year founded: 1989 Revenue: $11 - 100 million (2014 est.)

Supplier

Petasense

Petasense is an Industrial Internet of Things startup based in Silicon Valley. They make learning wireless sensors that connect to the cloud to democratize Predictive Maintenance for industrial customers. The vision of the company is to connect, collect and predict for the industrial world to improve operational efficiency and reduce costs.

Supplier

Blue Maestro

Blue Maestro develop health and environmental monitoring and control devices utilising the latest in low energy wireless and smartphone technology. With a keen focus on design and an approach that challenges traditional rules on how products must look, feel and be interacted with they seek to create products that are not only incredibly powerful through smartphone and internet connectivity but are also aesthetically pleasing and feel special to use.