下载PDF

Nanoprecise Sci Corp

自动预测性维护

概述

公司介绍

Nanoprecise 创建了一个“正在申请专利”的解决方案(硬件 + 软件),该解决方案结合了物理学、材料科学和数据分析来诊断机械问题并检测异常,表征故障组件并预测“剩余故障时间”。自 Nanoprecise 于 2017 年 12 月成立以来,其客户遍及石油和天然气、采矿、公用事业、暖通空调和基础设施领域。

物联网解决方案

Nanoprecise 的传感器是世界上第一个从一个传感器中提取 RPM、振动、声音、温度和湿度信息的传感器。该软件(基于目前仅限于研究论文的人工智能算法)分析来自各种传感元件的数据,并实现异常检测、故障表征和剩余使用寿命预测。这种端到端解决方案可以经济高效地部署,并且可以在世界上任何行业的任何机器上使用。 Nanoprecise 开发了 VibrationLF,这是一种预测性维护解决方案,结合了基于纳米技术和复杂机器学习技术的无线传感器,可准确诊断旋转设备中的故障并提供更换预测时间,从而使维护团队能够计划其维护活动。

主要客户

AltaSteel、Hindustan Zinc、Iffco、BJ

物联网应用简介

技术栈

Nanoprecise Sci Corp的技术栈描绘了Nanoprecise Sci Corp在传感器等物联网技术方面的实践。

-

设备层

-

边缘层

-

云层

-

应用层

-

配套技术

技术能力:

无

弱

中等

强

实例探究.

Case Study

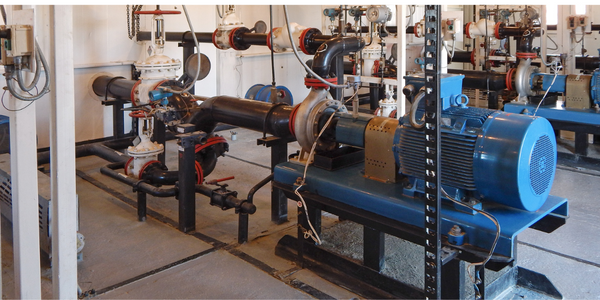

Detecting Cavitation And High Vane Pass Frequency For Pumps

The Condensate Cooling Water (CCW) pump, one of the critical pumps in maintaining steadystate operations, is a horizontal vane pump operating at up to 1650 m3/hr with a discharge pressure of 9 MPa (62 psi) at 986 rpm. Each day this pump is offline costs the plant $250,000 in lost revenue and each failure costs tens of thousands of dollars to execute an unplanned repair. Thus, Larsen & Toubro (L&T) really needed a predictive maintenance solution to detect faults at an early stage and provide a reliable prediction of Remaining Useful Life (RUL)

Case Study

Detection of a Bearing Outer Race Failure on a critical pump saved downtime cost

The process condensate pump, one of the critical pumps in the manufacturing process, has a history of failures every 6 to 12 months. It is a centrifugal pump operating at 3000 rpm with a discharge pressure of 28 MPa (400 psi). Each day this pump is offline, it costs the plant as much as $145,000 in lost production and each failure costs tens of hundreds of dollars to execute an unplanned repair. Nanoprecise Sci Corp was asked to implement a predictive maintenance solution in order to detect faults at an early stage and provide a reliable prediction of Remaining Useful Life (RUL).

Case Study

Automatic monitoring of acoustic emission saves catastrophic failure

Traditional measurement tools are ineffective when it comes to slowly rotating equipment. There are faults like Bearing Failure, Ring Plugging, Gear Tooth Crack and many more which can lead to the shutdown of machines. 1 minute of downtime cost the company $10. RingPluggingis a very common issue which Pinnacle Pellet was facing very frequently due to diverse feed quality into the machines. Product ring plugging can be detected as sound levels increase in specific roller bearings.

同类供应商.

Supplier

Adroit Technologies

Adroit Technologies is a privately held software development company that has been developing award winning real-time software for the industrial automation markets for over 25 years. The principal activities of the company are product development, consulting and solutions development, primarily in the industrial sector. Year founded: 1989 Revenue: $11 - 100 million (2014 est.)

Supplier

Petasense

Petasense is an Industrial Internet of Things startup based in Silicon Valley. They make learning wireless sensors that connect to the cloud to democratize Predictive Maintenance for industrial customers. The vision of the company is to connect, collect and predict for the industrial world to improve operational efficiency and reduce costs.

Supplier

Blue Maestro

Blue Maestro develop health and environmental monitoring and control devices utilising the latest in low energy wireless and smartphone technology. With a keen focus on design and an approach that challenges traditional rules on how products must look, feel and be interacted with they seek to create products that are not only incredibly powerful through smartphone and internet connectivity but are also aesthetically pleasing and feel special to use.