Download PDF

Senseye

Overview

HQ Location

United Kingdom

Year Founded

2014

Company Type

Private

Revenue

< $10m

Employees

51 - 200

Website

Twitter Handle

Company Description

Senseye is the leading cloud-based software for Predictive Maintenance. It helps manufacturers avoid downtime and save money by automatically forecasting machine failure without the need for expert manual analysis. Its intelligent machine-learning algorithms allow it to be used on any machine from any manufacturer, taking information from existing Industrial IoT sensors and platforms to automatically diagnose failures and provide the remaining useful life of machinery.

IoT Solutions

Senseye PdM is an industrial operations software tool, designed to be used on the shop-floor by the maintenance and operations people who need to keep things running smoothly and ensure that unplanned downtime stays down.

Like all good Industry 4.0 / Industrial IoT software, Senseye PdM is designed to integrate seamlessly and provide maximum value by leveraging your existing investments. It focuses on automatically delivering advanced Predictive Maintenance insights in an easily understandable manner.

Like all good Industry 4.0 / Industrial IoT software, Senseye PdM is designed to integrate seamlessly and provide maximum value by leveraging your existing investments. It focuses on automatically delivering advanced Predictive Maintenance insights in an easily understandable manner.

IoT Snapshot

Senseye is a provider of Industrial IoT application infrastructure and middleware, analytics and modeling, functional applications, sensors, and infrastructure as a service (iaas) technologies, and also active in the automotive, construction and infrastructure, electronics, oil and gas, and retail industries.

Technologies

Use Cases

Functional Areas

Industries

Services

Technology Stack

Senseye’s Technology Stack maps Senseye’s participation in the application infrastructure and middleware, analytics and modeling, functional applications, sensors, and infrastructure as a service (iaas) IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

Case Study

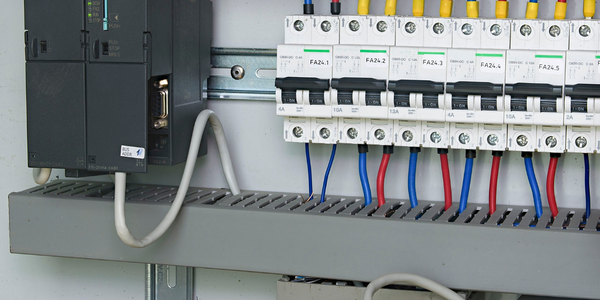

Predictive maintenance in Schneider Electric

Schneider Electric Le Vaudreuil factory in France is recognized by the World Economic Forum as one of the world’s top nine most advanced “lighthouse” sites, applying Fourth Industrial Revolution technologies at large scale. It was experiencing machine-health and unplanned downtime issues on a critical machine within their manufacturing process. They were looking for a solution that could easily leverage existing machine data feeds, be used by machine operators without requiring complex setup or extensive training, and with a fast return on investment.

Case Study

Scalable Predictive Maintenance in Nissan

With an abundance of data and insufficient skilled resources to perform analysis, Nissan were keen to expand the benefits of using data to influence maintenance. It decided to embark on a Condition Based maintenance programme to reduce production downtime by up to 50% across thousands of diverse assets. It was attracted to Senseye by its strong prognostics offering underpinned by machine learning.

Case Study

Nissan Manufactures Vehicles in 20 Countries

With an abundance of sensor data but insufficient skilled resources to perform manual analysis, Nissan was keen to expand the benefits of using data and machine learning to influence maintenance. In 2016, it decided to embark on a Predictive Maintenance program to reduce production downtime by up to 50% across thousands of diverse machines.It was attracted to Senseye by its deep domain experience and ability to scale across its sites, underpinned by its patented Artificial Intelligence technology.

Similar Suppliers.

Supplier

MachineMetrics

MachineMetrics is the authority on real-time manufacturing analytics. When we started MachineMetrics, we identified undeniable gaps in current manufacturing processes: a lack of real-time production visibility and a lack of communication between machine operators and their managers. Roughly 50% of US companies admitting to not having a systematic roadmap toward Digital Manufacturing solutions nor automation and over 90% of companies have yet to attempt to integrate solutions to date. Many companies have attempted to develop solutions for this problem but it had yet to be truly solved. We spoke with 100+ manufacturers to gather their feedback on why these solutions did not fit their needs and how it could be designed better.MachineMetrics was thus created; an IIoT manufacturing analytics and machine monitoring platform to help companies visualize where they stand now and overcome the challenges along the Digital Transformation journey to advance forward from reactivity, to proactivity, and to predictivity. Our fully automated machine monitoring solution provides visualizations of real-time manufacturing production data, instant notifications, as well as historical analytics, allowing factory workers to make faster, smarter, more confident decisions based on real-time data.We've simplified IoT for the shop floor and are empowering manufacturers to develop their roadmap toward manufacturing excellence with the easiest to use and simplest to integrate software on the market. MachineMetrics is driving manufacturing efficiency by more than 20% on average for our customers and we are proud to be developing the future of manufacturing alongside them.

Supplier

Sight Machine

Sight Machine specializes in manufacturing analytics and used by Global 500 companies to make better, faster decisions about their operations. Sight Machine's analytics platform, purpose-built for discrete and process manufacturing, uses Artificial Intelligence, Machine Learning, and advanced analytics to help address critical challenges in quality and productivity throughout the enterprise. The platform is powered by the industry's only Plant Digital Twin, which enables real-time visibility and actionable insights for every machine, line, and plant throughout an enterprise. Founded in Michigan in 2011 and expanded to the Bay Area in 2012, Sight Machine fuses the spirit of Silicon Valley technology innovation with rock-solid Detroit manufacturing. Our team includes the founders of Slashdot along with leadership from early Yahoo, Palantir, Tesla, Cisco, IBM, McKinsey, and Apple.

Supplier

Peak

Peak offers a Decision Intelligence platform that doesn’t just deliver models, it delivers results. It is a single platform that can help you rapidly deploy multiple AI-powered solutions on a single platform. It takes you all the way from siloed data and systems, to putting AI in the hands of commercial decision makers. It is built to empower you to make superhuman decisions, all the time.