下载PDF

Delivers Seamless Scalability to IOTATOI

技术

- 平台即服务 (PaaS) - 数据管理平台

适用行业

- 电池

适用功能

- 现场服务

用例

- 机器状态监测

挑战

IOTATOI 是 Power Agent Systems 的一个部门,它开发了一种称为通用监控系统 (UMS) 的边缘服务器。 IOTATOI 使用 UMS 作为边缘层数据收集器来监控制造、矿山和化工厂中的备用电池阵列。这种备用电池的经验使 IOTATOI 将系统扩展到可以通过传感器监测的任何条件,例如振动、热量、温度和流量。 IOTATOI 发现他们需要从原来的中间件转移到可以实现更大可扩展性的东西,并以更广泛的方式呈现信息,从而使他们能够动态查看信息并执行基准分析,将数据输入分析引擎并创建一个更具可操作性的观点。

客户

IOTATOI

关于客户

IOTATOI (IO-TA-Toy) 提供了一种经济高效的方式来管理和协调实时全面监控所需的所有不同元素。从数据收集到运营管理再到分析和数据集成,IOTATOI 扩展了

解决方案

IOTATOI 已经开发出连接所有传感器并将其带到集中位置的物理能力。 Thingworx 使我们能够无缝扩展该信息,从任何位置查看信息,将信息推送到任何位置,并执行一些他们现有中间件无法完成的独特事情。将 ThingWorx 添加到 UMS 意味着 IOTATOI 可以让客户请求特定的表示或使用他们需要的确切传感器进行报告。 IOTATOI 可以创建混搭、设置传感器、配置数据的发送位置,并在发货时使用预配置的所有内容启用它。然后客户在他们的网站上部署盒子;调用 IOTATOI 来验证解决方案是否按照配置运行,然后他们可以监控其设备上的 5、10、15、20 或更多传感器,而这一切都只是历史成本的一小部分。要获得 ThingWorx 8 的免费演示:http://solutions.iotone.com/thingworx

收集的数据

Backup, Battery Charge Level, Fluid Flow Rates, Temperature, Vibration

运营影响

数量效益

相关案例.

Case Study

Battery manufacturer Industrial Digital Twin

For optimum control of product quality, Banner relies on a high production depth. Its 560 production employees produce nearly all the components in¬-house that they need to make finished batteries on Banner’s six assembly lines. This includes the plastic parts for the battery cases as well as the paste-filled lead oxide grids. Their production involves two to five¬ days rest in maturing chambers to create optimum current absorption and storage capacity. Banner’s ongoing success was accompanied by a continuous, organic growth of the production facilities, adding or extending hall after hall until the complex filled the site that had seemed ever so spacious when the company moved here from a smaller place in 1959. These developments led to a heterogeneous production environment. “This confronts us with significant challenges, particularly concerning intra¬logistics issues, such as scheduling for the maturing chambers,” says Franz Dorninger, technical director at Banner. “We contemplated various ways to overcome this problem, including relocating to new premises.”

Case Study

GM Global Battery Systems Lab

Testing expensive battery prototypes is an around-the-clock job for the engineers at GM’s Global Battery Systems Lab. Excessive heat or high voltage can make batteries unstable or vulnerable to damage. Confirming the reason for the alarm and eliminating fault alerts sometimes requires onsite investigation, often at non-business hours.

Case Study

Flow Battery Technology Changes Energy Distribution

The size of the cell stacks and the costly materials needed for construction of traditional flow batteries have kept the technology from becoming commercially viable. The solution is needed to make the stacks smaller and less expensive without losing any of the power.

Case Study

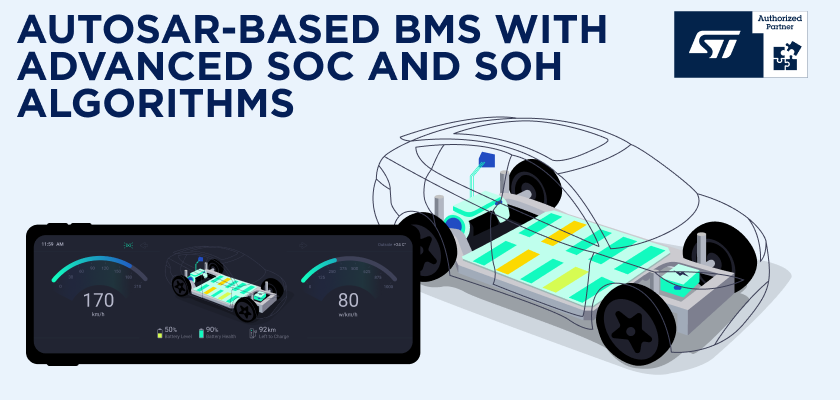

AUTOSAR-based Battery Management System

We aimed to build an advanced BMS with improved accuracy of SoC and SoH algorithms for hybrid electric and electric vehicles. Our demo was built using automotive grade components and designed to conform to ASIL-D certification. The scope of work covered such safety features as Over/Under Voltage, Over/Under Temperature Protection, Short Circuit Detection, Cell Balancing, CAN Communication, and Faults Handling. Read the full case

Case Study

LoRaWAN - Helping citizens and organizations to reduce environmental impact

More and more, our world is becoming aware about the environmental print that comes with population growth, limitation of resources, climate change and the need for sustainability. The biggest challange here was to raise awareness among citizens and organizations about their environmental impact, and to help themto reduce it in a sustainable way with the help of Real time data.