下载PDF

Enhancing Safety and Efficiency at Tomago Aluminium with K2 Software

技术

- 网络安全和隐私 - 身份认证管理

- 网络安全和隐私 - 安全合规

适用行业

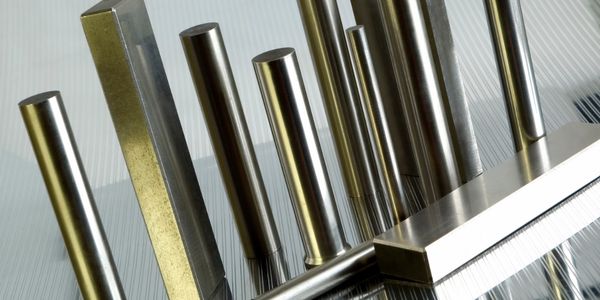

- 金属

- 造纸

适用功能

- 质量保证

用例

- 现场人员安全管理

- 时间敏感网络

挑战

澳大利亚最大的铝冶炼厂 Tomago Aluminium 正在努力解决 IT 基础设施脱节以及过度依赖纸质表格和基于电子邮件的流程的问题。这导致潜在安全问题缺乏透明度和可见性,难以确保任务安全执行和安全问题得到及时解决。该公司使用 SharePoint 内的调查和纸质表格来进行挽救生命的控制,这造成了安全风险并使报告变得困难。此外,该公司每天必须审核 840 个罐子,这个过程既乏味又耗时。从罐中收集的数据必须手动记录,然后输入到共享电子表格中,这个过程很容易出错且效率低下。

关于客户

Tomago Aluminium 是澳大利亚最大的铝冶炼厂,自 1983 年以来每天 24 小时运营。该公司每年为澳大利亚经济贡献 15 亿美元,其中 8 亿美元用于当地。该冶炼厂每年生产58.5万吨铝,占澳大利亚原铝的25%。 90%的产品出口到亚太地区。该公司拥有 840 个罐子,这些罐子对业务极其重要,因为任何不稳定都可能使公司损失数百万美元。因此,快速发现并解决问题对于企业至关重要。

解决方案

Tomago Aluminium 使用 K2 Software 实施了多种解决方案,以实现关键流程的自动化。该软件允许该公司利用 SQL 数据库并将解决方案与 SAP 集成,从而灵活地开发其他业务解决方案以提高效率并削减成本。救生控制过程是自动化的,使员工能够自动记录问题并轻松检查安全任务的状态。该公司还实现了底池审计流程的自动化。审计员现在使用手机和手写笔在现场输入数据,当他们返回办公桌时,数据就会得到整合。使用适当的数据和图表自动生成 Power BI 报告,并将副本通过电子邮件发送给所有必要的各方。该公司还实现了十多个其他流程的自动化,包括法定合规性和承包商入职。

运营影响

数量效益

相关案例.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.

Case Study

Continuous Casting Machines in a Steel Factory

With a very broad range of applications, steel is an important material and has been developed into the most extensive alloy in the engineering world. Since delivering high quality is absolutely crucial for steel plants, ensuring maximum productivity and the best quality production are the keys to competitiveness in the steel industry. Additionally, working conditions in steel factories are not suitable for workers to stay in for long periods of time, so manufactures usually adopt various machines to complete the steel production processes. However, the precision of these machines is often overestimated and the lack of flexibility also makes supervisors unable to adjust operating procedures. A renowned steel factory in Asia planned to improve its Distributed Control System (DCS) of furnaces as well as addressing the problem of insufficient accuracy. However, most well-known international equipment suppliers can not provide a satisfactory solution and local maintenance because the project needed new technologies to more accurately control equipment operations. By implementing Advantech’s automated monitoring and control solution, steel factories can not only improve the manufacturing processes but can also allow users to add additional functions to the existing system so as to make sure the operation runs at high efficiency.

Case Study

Automated Predicitive Analytics For Steel/Metals Industry

Asset to be monitored: Wire Compactor that produces Steel RebarCustomer Faced The Following Challenges:Dependent upon machine uptime.Pressure cylinders within the compactor fail to control compression and speed causing problems in binding the coil.Equipment failure occurs in the final stage of production causing the entire line to stop, can you say bottleneck?Critical asset unequipped with sensors to produce data.