下载PDF

GM Global Battery Systems Lab

适用行业

- 电池

挑战

对于通用汽车全球电池系统实验室的工程师来说,测试昂贵的电池原型是一项全天候的工作。过热或高压会使电池不稳定或容易损坏。确认警报原因并消除故障警报有时需要现场调查,通常在非工作时间进行。

客户

通用汽车 (GM) 全球电池系统实验室

关于客户

通用汽车 (GM) 全球电池系统实验室负责测试用于通用汽车的所有锂离子电池。作为加速采用电动汽车计划的一部分,这个拥有 38 名员工的实验室测试原型和生产电池。

解决方案

该团队在 BlackBerry Corporate Developer Program 的指导下使用 Java 来开发 General Motors LABerry 应用程序。自定义应用程序链接到实验室的监控和警报软件,以便工程师在他们的黑莓智能手机上接收详细的测试信息。解决方案评估 - 类型:IT - 成熟度:高(技术已投放市场超过 5 年) 软件组件 - BlackBerry Enterprise Server - General Motors LABerry - Research In Motion (RIM) 企业开发人员计划 (CDP)

收集的数据

Control System Alert, Device Diagnostic Status, Fault Detection, Man Hours, Production Efficiency

运营影响

相关案例.

Case Study

Battery manufacturer Industrial Digital Twin

For optimum control of product quality, Banner relies on a high production depth. Its 560 production employees produce nearly all the components in¬-house that they need to make finished batteries on Banner’s six assembly lines. This includes the plastic parts for the battery cases as well as the paste-filled lead oxide grids. Their production involves two to five¬ days rest in maturing chambers to create optimum current absorption and storage capacity. Banner’s ongoing success was accompanied by a continuous, organic growth of the production facilities, adding or extending hall after hall until the complex filled the site that had seemed ever so spacious when the company moved here from a smaller place in 1959. These developments led to a heterogeneous production environment. “This confronts us with significant challenges, particularly concerning intra¬logistics issues, such as scheduling for the maturing chambers,” says Franz Dorninger, technical director at Banner. “We contemplated various ways to overcome this problem, including relocating to new premises.”

Case Study

Delivers Seamless Scalability to IOTATOI

IOTATOI is a division of Power Agent Systems that has developed an edge server called the Universal Monitoring System (UMS). IOTATOI is using UMS as an edge tier data collector to monitor backup battery arrays in manufacturing, mines, and chemical plants. This experience with battery backups led IOTATOI to expand the system to any condition that can be monitored by sensors such as vibration, heat, temperature, and flow. IOTATOI found they needed to move from their original middleware to something that would allow greater scalability and to also present information in a much broader way allowing them to dynamically look at the information and perform benchmarking analysis, feeding the data into analytics engines and creating a much more actionable view.

Case Study

Flow Battery Technology Changes Energy Distribution

The size of the cell stacks and the costly materials needed for construction of traditional flow batteries have kept the technology from becoming commercially viable. The solution is needed to make the stacks smaller and less expensive without losing any of the power.

Case Study

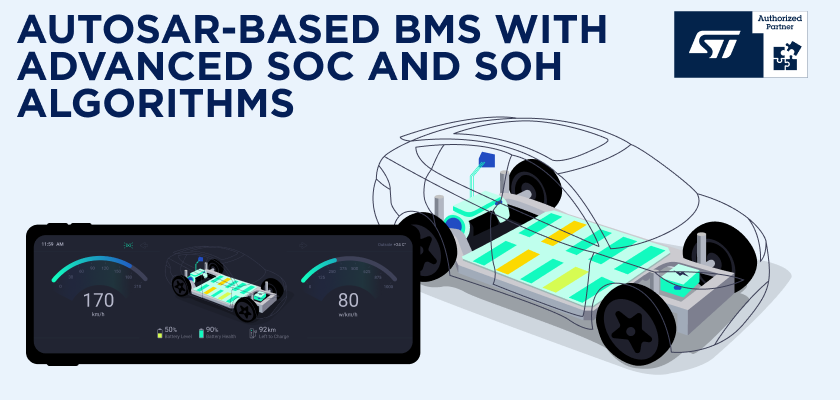

AUTOSAR-based Battery Management System

We aimed to build an advanced BMS with improved accuracy of SoC and SoH algorithms for hybrid electric and electric vehicles. Our demo was built using automotive grade components and designed to conform to ASIL-D certification. The scope of work covered such safety features as Over/Under Voltage, Over/Under Temperature Protection, Short Circuit Detection, Cell Balancing, CAN Communication, and Faults Handling. Read the full case

Case Study

LoRaWAN - Helping citizens and organizations to reduce environmental impact

More and more, our world is becoming aware about the environmental print that comes with population growth, limitation of resources, climate change and the need for sustainability. The biggest challange here was to raise awareness among citizens and organizations about their environmental impact, and to help themto reduce it in a sustainable way with the help of Real time data.