下载PDF

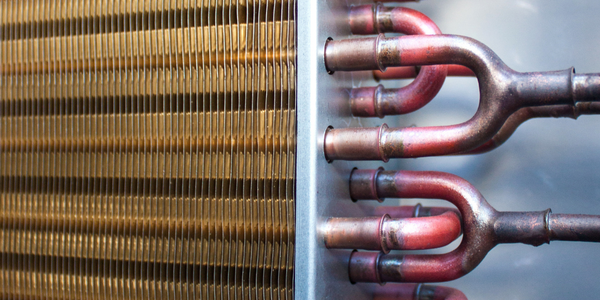

Heat Exchanger Monitoring and End of Cycle Prediction

技术

- 分析与建模 - 预测分析

适用功能

- 维护

用例

- 预测性维护

挑战

预测由于结垢导致的热交换器的循环结束 (EOC) 是炼油厂面临的一个持续挑战。主动预测何时需要清洁换热器可以实现基于风险的维护计划和优化处理速率、运营成本和维护成本。在使用 Seeq 之前,工程师必须在电子表格中手动合并数据条目,并在必要时(例如设备停止服务时)花费数小时/天来格式化和过滤内容或删除不相关的数据。

客户

未公开

关于客户

-

解决方案

使用 Seeq 公式工具代替耗时的电子表格来监控换热器性能,将为工程师节省数周的工作时间,让他们腾出时间来执行其他有价值的公司任务。相同的公式可以应用于许多其他交换器,因此用户可以专注于其他持续改进项目,而不是持续监控许多电子表格。由于改进周转计划和其他改进机会,每年可以节省数百万美元。

收集的数据

Process Data Historian, Heat Exchanger Design Data

运营影响

相关案例.

Case Study

Remote Monitoring & Predictive Maintenance App for a Solar Energy System

The maintenance & tracking of various modules was an overhead for the customer due to the huge labor costs involved. Being an advanced solar solutions provider, they wanted to ensure early detection of issues and provide the best-in-class customer experience. Hence they wanted to automate the whole process.

Case Study

Predictive Maintenance for Industrial Chillers

For global leaders in the industrial chiller manufacturing, reliability of the entire production process is of the utmost importance. Chillers are refrigeration systems that produce ice water to provide cooling for a process or industrial application. One of those leaders sought a way to respond to asset performance issues, even before they occur. The intelligence to guarantee maximum reliability of cooling devices is embedded (pre-alarming). A pre-alarming phase means that the cooling device still works, but symptoms may appear, telling manufacturers that a failure is likely to occur in the near future. Chillers who are not internet connected at that moment, provide little insight in this pre-alarming phase.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

Asset Management and Predictive Maintenance

The customer prides itself on excellent engineering and customer centric philosophy, allowing its customer’s minds to be at ease and not worry about machine failure. They can easily deliver the excellent maintenance services to their customers, but there are some processes that can be automated to deliver less downtime for the customer and more efficient maintenance schedules.