Download PDF

Accelerate: Academic, Scientific and Industrial Research DDN Storage Empowers Pawsey Supercomputing Center to Speed Scientific Discoveries that Reveal the Secrets of the Universe

Technology Category

- Infrastructure as a Service (IaaS) - Cloud Storage Services

- Application Infrastructure & Middleware - Data Exchange & Integration

Applicable Industries

- Education

- Aerospace

Applicable Functions

- Product Research & Development

- Business Operation

Use Cases

- Predictive Maintenance

- Edge Computing & Edge Intelligence

- Real-Time Location System (RTLS)

Services

- Cloud Planning, Design & Implementation Services

- Data Science Services

The Challenge

The Pawsey Supercomputing Center in Perth, Western Australia, is one of the most powerful facilities in the Southern Hemisphere. It supports scientific breakthroughs in radio astronomy, energy resources, and engineering. At any given point, more than a thousand scientists rely on Pawsey’s state-of-the-art facilities to conduct data-intensive research, complex simulations, and advanced visualizations. The Center also plays a pivotal role in the trailblazing Square Kilometer Array (SKA) project, which focuses on building a next-generation radio telescope that will be more sensitive and powerful than today’s most advanced telescopes to survey the universe with incredible depth and speed. The SKA project will generate massive amounts of data from thousands of connected antennae, giving astronomers unprecedented insights into the formation of the universe. To support this ground-breaking research, Pawsey must provide scientists around the world with easy access to high-end computing platforms and resilient, scalable storage.

About The Customer

The Pawsey Supercomputing Center in Perth, Western Australia, is one of two tier 1 high-performance computing (HPC) centers in Australia and one of the most powerful facilities in the Southern Hemisphere. Pawsey supports scientific breakthroughs in radio astronomy, energy resources, and engineering. At any given point, more than a thousand scientists rely on Pawsey’s state-of-the-art facilities to conduct data-intensive research, complex simulations, and advanced visualizations. The Center also plays a pivotal role in the trailblazing Square Kilometer Array (SKA) project, which focuses on building a next-generation radio telescope that will be more sensitive and powerful than today’s most advanced telescopes to survey the universe with incredible depth and speed. According to Neil Stringfellow, executive director of the Pawsey Supercomputing Center, the SKA project will generate massive amounts of data from thousands of connected antennae, giving astronomers unprecedented insights into the formation of the universe.

The Solution

The Pawsey Supercomputing Center sought reliable high-performance, high-density disk infrastructure that would provide the flexibility to scale storage both out and up as needed. The ability to plug seamlessly into other existing tape and cloud storage as well as back-end systems was important, as was the ability to address the Center’s diverse research requirements. After weighing all its selection criteria, Pawsey deployed two DDN GS12K storage appliances with 5 PBs of storage capacity, supporting an array of game-changing scientific discoveries, including the Desert Fireball Network (DFN) project. One of the first projects to take advantage of the new DDN storage, DFN uses cameras to track fireballs as they shoot across the Australian desert night sky, aiding in the discovery and retrieval of newly fallen meteorites. After ingestion, this network of images then resides on the DDN GS12Ks. Researchers work with metadata to triangulate events that facilitate rapid meteorite recovery.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

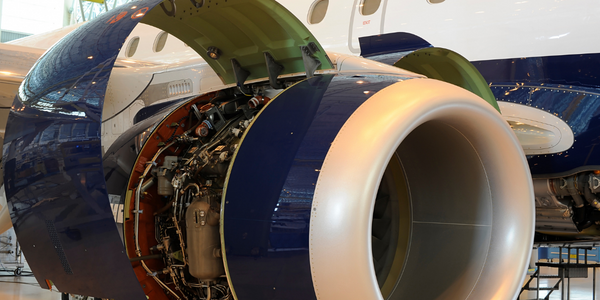

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Developing Smart Tools for the Airbus Factory

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.