Alcan Achieves Early Start Up with AMS

- Automation & Control - Distributed Control Systems

- Platform as a Service (PaaS) - Device Management Platforms

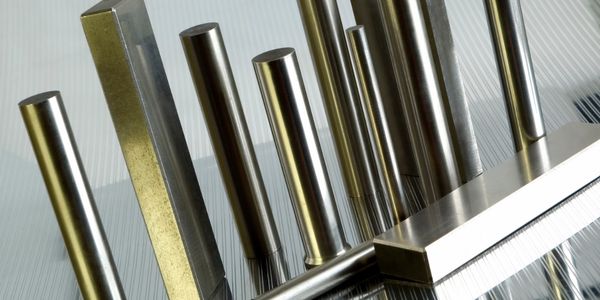

- Metals

- Process Manufacturing

- Machine Condition Monitoring

- Process Control & Optimization

Alcan had a tight schedule to expand its bauxite to alumina mineral processing refinery from 2.2 to 3.8 million tons. Alcan’s challenge included balancing the capital cost, minimizing the number of construction personnel on-site, integrate the green-field and brown-field facilities without affecting current operating facilities whilst achieving project budget, schedule and quality.

Alcan decided to expand using a Pre-Assembled Module (PAM) concept which enabled all modules to be built offsite in Thailand and Vietnam. By using Emerson's DeltaV and AMS Device Manager to pre-commission FOUNDATION fieldbus devices, Alcan significantly reduced man-hours and experienced cost savings. Software Components - DeltaV and AMS Device Manager

Related Case Studies.