Download PDF

Data Engineering for Enabling Condition Monitoring of Industrial Equipment

Technology Category

- Networks & Connectivity - MQTT

- Platform as a Service (PaaS) - Application Development Platforms

Applicable Industries

- Aerospace

- Automotive

Use Cases

- Asset Health Management (AHM)

- Structural Health Monitoring

Services

- Data Science Services

- System Integration

The Challenge

The instrument engineering company faced a significant challenge in managing the data acquisition from various devices and sensors. Each device or sensor had its unique technology and served a different purpose, requiring a separate data acquisition platform. This led to a scattered product portfolio, disconnected sales process, and low customer perception. The company's end customers, large industrial enterprises, often needed to work with multiple devices or products, which meant dealing with different platforms. This situation resulted in a large effort and resources required to maintain these platforms, and a slow and lengthy time-to-market. The company also faced a lack of standard functionality across platforms.

The Customer

Not disclosed

About The Customer

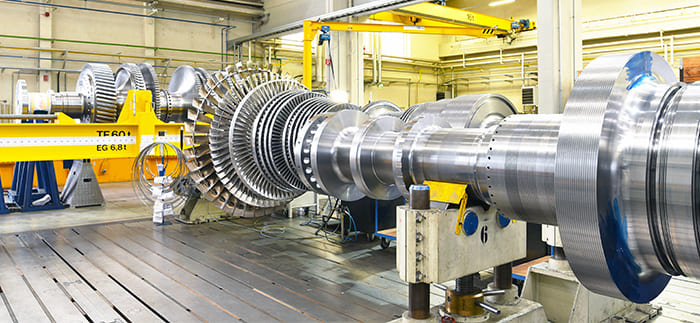

The customer is a European instrument engineering company that manufactures data acquisition systems (DAQ). These systems enable critical testing, measurement, and monitoring applications for aerospace, industrial, and automotive industries. The DAQ systems acquire data in real-time for different physical quantities using sensor technologies, enable high measurement accuracy due to patented technology, and integrate with various enterprise software applications like LabView, Visual Studio .NET, and more. The company's end customers are large industrial enterprises that may need one or multiple devices or products for their applications.

The Solution

To address these challenges, the company partnered with Saviant to develop a robust condition monitoring platform with smart analytics and AI capabilities. The solution involved building an end-to-end data engineering capacity throughout their data acquisition, organization, analytics, and action procedures. The platform was designed to acquire data from a wide variety of sources in real-time and make it available to a variety of applications for further analysis. The team of 20 technology consultants and developers used .Net core, GraphQL, OPC UA, and MQTT for device discovery protocols. The platform captured data from various sources and platforms in real time, orchestrated it, and delivered it to a variety of applications via APIs. This resulted in a complete sensor to software platform, opening interfaces to customers across various levels, standardization across platforms, platform independence, scalability, and security.

Operational Impact

Related Case Studies.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.