下载PDF

Getting the Torque Just Right Could Save Millions for Aerospace Companies

技术

- 分析与建模 - 虚拟和增强现实(AR/VR)软件

- 网络与连接 - WiFi

- 可穿戴设备 - 增强现实(AR)眼镜/耳机/控制器

适用行业

- 航天

适用功能

- 离散制造

用例

- 增强现实

挑战

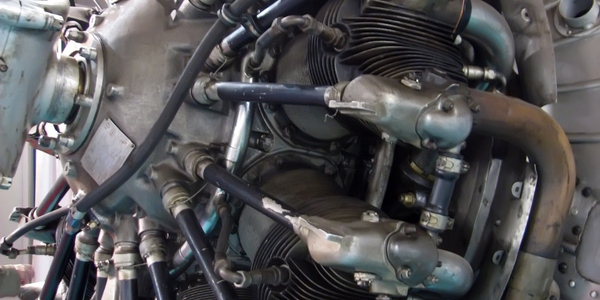

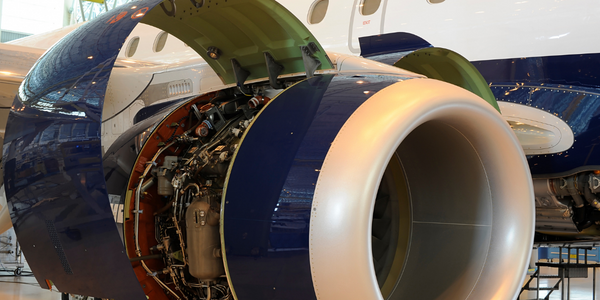

GE Aviation 每年因发动机组装和大修过程中关键点的错误而损失数百万美元。成本体现在生产力损失、测试延迟、客户交付延迟以及排除故障和纠正故障所需的工时。如果直到将发动机发送给客户后才检测到错误,维修成本将成倍增加。

B 型螺母就是这样的关键制造点之一。它们在飞机发动机流体管路和软管中发挥着关键作用,提供坚固、可靠的密封——但前提是正确拧紧和拧紧。如果没有正确拧紧,则需要重新进行维护、取消飞行,甚至在飞行中停机。

客户

GE航空

关于客户

GE Aviation 是通用电气的子公司,总部位于俄亥俄州埃文代尔,位于辛辛那提郊外。 GE Aviation 是顶级飞机发动机供应商之一,为大多数商用飞机提供发动机。通用电气阿维

解决方案

GE Aviation 启动了一项结合了三种技术的 AR 部署:Upskill 的 Skylight、Glass Enterprise Edition 智能眼镜和支持 Wi-Fi 的 Atlas-Copco Saltus MWR-85TA 扭矩扳手。

使用 Skylight on Glass,机械师在执行不同的维护任务时直接在他们的视线内接收分步指导说明和图像。当机械师通过标准程序并到达需要应用扭矩扳手的步骤时,Skylight 通过智能眼镜提醒他们,然后在机械师继续之前实时验证正确的值。

收集的数据

Fault Detection, Instructions, Process Procedure

运营影响

数量效益

相关案例.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Developing Smart Tools for the Airbus Factory

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.