下载PDF

Kitron's Digital Transformation: Enhancing Supply Chain and Manufacturing Efficiency

技术

- 功能应用 - 库存管理系统

- 功能应用 - 制造执行系统 (MES)

适用行业

- 航天

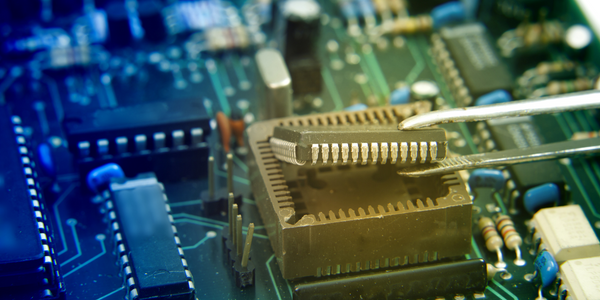

- 电子产品

适用功能

- 物流运输

- 产品研发

用例

- 添加剂制造

- 供应链可见性(SCV)

挑战

支持全球供应链

Kitron 的增长目标很高,目标是收入增长 30%。由于该公司正在处理小批量生产的高复杂性产品,这转化为对供应链、变化的灵活性、安全性,当然还有效率的关注。生产是他们的核心业务,拥有业内最好的组装能力之一。寻找最佳供应商也是重中之重。

在 2009 年围绕 IFS 将其运营标准化后,实施后最重要的要素之一就是展示结果。董事会明确表示,他们希望看到投资回报。以解决方案能力中心的形式成立了一个团队,以确保结果和持续改进。

客户

基特隆

关于客户

Kitron是一家领先的电子制造服务 (EMS) 公司,业务遍及挪威、瑞典、立陶宛、德国、波兰、中国和美国。该公司于 1960 年代初在挪威阿伦达尔成立。 Kitron 的总部现在位于挪威的 Asker。 Kitron 在欧洲、亚洲和美国的六个不同国家/地区拥有 1700 名员工。

解决方案

更智能的物料计划

现在 Kitron 正在将 IFS 用于供应链、集成、配置和需求驱动的物料需求计划 (MRP),这有可能将库存减少 40% 并将交货时间减少 80%。 MRP 使制造商能够访问其当前零件的界面,并查看以红色突出显示的需要重新订购的零件。从而实现更敏捷的供应链管理。

能力也是他们最大的成本,与材料一起,进行正确的投资以保持高创新率变得越来越重要。最近,Kitron 除了在立陶宛的自主生产线外,还为其瑞典工厂购买了四台新的 ABB Yumy 自动化机器人。

运营影响

数量效益

相关案例.

Case Study

Remote Temperature Monitoring of Perishable Goods Saves Money

RMONI was facing temperature monitoring challenges in a cold chain business. A cold chain must be established and maintained to ensure goods have been properly refrigerated during every step of the process, making temperature monitoring a critical business function. Manual registration practice can be very costly, labor intensive and prone to mistakes.

Case Study

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.