下载PDF

SpaceX delivers outer space at bargain rates

技术

- 分析与建模 - 数字孪生/模拟

适用行业

- 航天

适用功能

- 产品研发

用例

- 虚拟原型与产品测试

挑战

Space X 希望开发一种火箭,可以将进入太空的成本降低 10 倍。

客户

太空探索技术公司

关于客户

SpaceX 设计、制造和发射先进的火箭和航天器。该公司成立于 2002 年,旨在彻底改变太空技术,最终目标是使人们能够生活在其他星球上。

解决方案

Space X 采用基于 NX 软件和 Teamcenter 软件的托管开发环境,创建整个火箭的虚拟模型,利用设计数据进行车间指导和营销,并控制所有火箭组件的生命周期。

运营影响

数量效益

相关案例.

Case Study

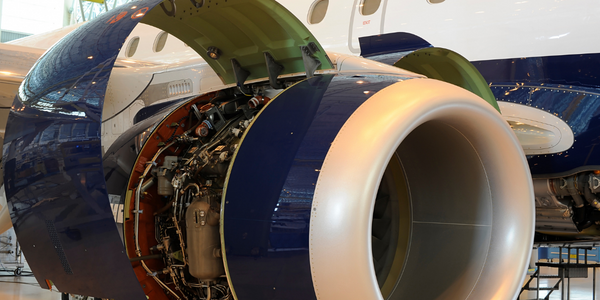

Airbus Soars with Wearable Technology

Building an Airbus aircraft involves complex manufacturing processes consisting of thousands of moving parts. Speed and accuracy are critical to business and competitive advantage. Improvements in both would have high impact on Airbus’ bottom line. Airbus wanted to help operators reduce the complexity of assembling cabin seats and decrease the time required to complete this task.

Case Study

Aircraft Predictive Maintenance and Workflow Optimization

First, aircraft manufacturer have trouble monitoring the health of aircraft systems with health prognostics and deliver predictive maintenance insights. Second, aircraft manufacturer wants a solution that can provide an in-context advisory and align job assignments to match technician experience and expertise.

Case Study

Aerospace & Defense Case Study Airbus

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

Case Study

Developing Smart Tools for the Airbus Factory

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.

Case Study

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.