Case Studies.

Our Case Study database tracks 8,303 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(23)

- (19)

- (4)

- (1)

-

(18)

- (7)

- (6)

- (5)

- View all

-

(16)

- (7)

- (6)

- (3)

- View all

-

(12)

- (6)

- (2)

- (2)

- View all

-

(12)

- (11)

- (1)

- (1)

- View all 10 Technologies

- (12)

- (7)

- (5)

- (4)

- (4)

- View all 21 Industries

- (12)

- (12)

- (11)

- (8)

- (3)

- View all 8 Functional Areas

- (24)

- (6)

- (5)

- (3)

- (2)

- View all 13 Use Cases

- (1)

- (3)

- (3)

- (2)

- (2)

- (2)

- View all 39 Suppliers

Selected Filters

59 case studies

|

National Grid Company

Adroit Technologies

NGC has a statutory duty under the Electricity Act 1989 to develop and maintain an efficient, co-ordinated and economical Transmission System for the supply of electricity. One of NGC’s statutory obligations is the requirement to maintain system frequency within the range 49.5Hz - 50.5Hz. This is achieved through the management of changing generation and/or demand. These services are automatic and can be required at any time to contain frequency deviations and recover it back to normal. To date these services have been provided by Generators, obliged to have a frequency control capability by virtue of their Grid Code connection conditions, and large industrial electricity consumers capable of interrupting firm loads for a required time. Given the limited number of production processes able to offer a firm interruptible load, NGC has been developing a frequency response service through the aggregation of fluctuating electrical loads. By combining a large number of cyclic demands, a relatively firm level of response can be derived and delivered when required.

|

|

Monitoring Industrial Power Distribution

Eclipse IoT

OmSense is a family of products to monitor and manage industrial sensors. Most of these sensors are found in computer centers or production environments with large energy requirements. As Kevin and John developed the product they wanted it to come preinstalled on industrial hardware, with the ability to be up-and-running within minutes of installation

|

|

The Power of Balancing Technology

Eurotech

Accurate balancing of the turbochargers used in cars and commercial vehicles is vital to ensure engine efficiency and longevity and it is carried out in both the manufacturing and remanufacturing of these units. If not measured and corrected through the balancing process, turbochargers will be noisy and in severe cases bearing failure can occur.

|

|

Sparks Dynamics Assists Atlas Container Secure a $15,000 BGE Energy Rebate

Sparks Dynamics

The ReMASTER Compressed Air Monitoring system was installed in 2015. This system is capable of monitoring compressed air system parameters on a continuous basis and transferring that information to a cloud server which can be accessed by Atlas Container personnel, Industrial Diagnostics and Sparks Dynamics. This information was collected into a database which can be exported to an Excel spreadsheet or displayed graphically using Sparks Dynamics ViewMaster Software. The average annual compressed air electricity expense was estimated to be approximately $116,000. This is based on an incremental $/KWh electric rate of $.091 per KWh and an estimated compressed air energy consumption of 1,279,200 KWH. The implementation phase of Energy Conservation Measures (ECMs) for the Compressed Air System included: • Identification and repair of compressed air leaks • Understanding of compressed air usage per manufacturing machine and installation of shut off valves when the machines are no longer in production mode • Identification of misapplications of compressed air to include blow offs, venturis, and cooling scenarios • Understand system pressure requirements and potential installation of point of use pressure regulation.

|

|

ASD Healthcare Delivers True Connected Care

Vodafone

ASD Healthcare’s Cubixx connected refrigeration solution was initially aimed at larger hospitals and pharmacies, utilising Wi-Fi or local area networks (LAN) for connectivity. With phase two, Cubixx would be rolled out to smaller practices and patients homes. The issue for ASD Healthcare was finding a single connectivity provider to cover the entire U.S., and facilitate international expansion.

|

|

Connected Field Services

ThingLogix

McKinley faced several challenges to implement these product improvements: - Which device hardware is best? - How do they connect their products and put them online? - How will their products communicate? - Which sensor protocols work best? - How will they develop the proper visualizations? - How do we integrate it with their field service technology? - How do they set up rules and their associated actions?

|

|

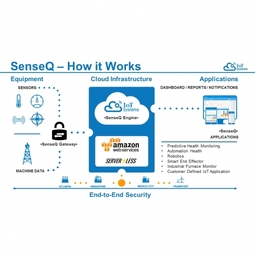

IoT Systems & InControl Engineering: Integrating Smart Sensors & Industrial IoT

IoT Systems

In 2016, Kevin Stoddard, a managing partner, had a problem. InControl’s customers required sensors on several equipment distributed across multiple sites and locations. To accomplish this, InControl needed a cost-effective solution fast. They also needed this solution to be intuitive for the equipment owners, highly secure, and broadly capable of delivering custom analytics to clients around the world.

|

|

FRoSTA Cuts Downtime with Anywhere-Anytime Alerts

FRoSTA AG is the German market leader in frozen fish and convenience foods and operates a fully automated raw materials warehouse in Bremerhaven, staffed by 600 employees. To run its warehouse, FRoSTA has a conveyor and four ASRS (Automated Storage and Retrieval Systems), controlled by a series of Siemens SIMATIC automated process controllers designed for warehouse applications.

|

|

SCADA System for Oil Pumping Rig RTUs

Ovak Technologies

To develop a supervisory control and data acquisition (SCADA) system for 10,000 remote terminal units (RTUs).

|

|

ZumIQ APPLICATION ENVIRONMENT: REMOTE MONITORING OF FIELD ASSETS

FreeWave Technologies

|

|

Using Data to Make Operators and Maintenance Staff Efficient

Microsoft

Some of Elipse's customers have very large plants, and when the technicians are out in the plant, they cannot see the status of plant instrumentation. When doing calibrations or inspections, they have to radio back to the control room, which slows the work and can extend downtime.

|

|

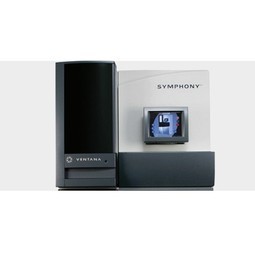

Improving Instrument Recovery Time and Reducing Downtime

PTC

While in the midst of developing SYMPHONY®, a fully automated slide staining system for standard Hematoxylin and Eosin (H&E) staining, Ventana realized that they required a remote service solution to ensure that customers received an exceptional level of service. However, with a tight timeline to develop and launch this new product, there was some reluctance to integrate additional software. “There was some internal reluctance toward implementing the remote service technology with our SYMPHONY instrument given the short timeframe,” explains Greg Dameron, Director of Development at Ventana. “In fact, the executive team informed me that if the software would delay the SYMPHONY launch by even one day, then we would not implement it at all.” The company began evaluating commercial remote service offerings, seeking a solution that would provide value to customers without disrupting system stability. “Our products are based on stability, so we needed the remote service technology to be stable as well,” says Dameron. Ventana sought to reduce instrument downtime to fewer than 24 hours by remotely monitoring all field instrumentation on a 24/7 basis. This would enable the abilities to remotely diagnose and repair issues, provide “over-the-shoulder” troubleshooting and training for users, and track inventory to automatically replenish reagents in real time. “We felt strongly that delivering remote service would help us achieve a response time that we could not otherwise meet,” says Dave Flaten, Vice President and General Manager of the Primary Staining business unit at Ventana. “We believed that it would become an integral part of the product line.”

|

|

Smart SCADA-based Deployable Communications & Information System

Adroit Technologies

Following the Fukushima incident in Japan, EDF-Energy NGL undertook a rigorous assessment into the resilience of its fleet of UK nuclear power stations against the highly unlikely occurrence of an extreme weather or other natural event. Through this process, they identified a requirement for the provision of mobile emergency response systems which will be deployed on the occurrence of such an event.

|

|

Improved Monitoring in Industrial Manufacturing Facility

Synapse Wireless

When your crane is moving tons of magma-hot iron, you can’t afford an unexpected failure. McWane Ductile knew monitoring the crane motor metrics within their facility could help prevent a mechanical failure that would strand an enormous bucket of molten metal overhead. Unfortunately, their legacy wired monitoring system couldn’t work with moving objects in this extreme environment. If they could integrate wireless capabilities into their existing equipment they could extend their monitoring capabilities without starting over from scratch.

|

|

Compression Facility Industrial Asset Monitoring Solution

Veros Systems

After spending millions on an enhanced oil recovery (EOR) infrastructure, including CO2, compressors, pipelines, injection wellheads, and fluid separators, Chaparral began to see its long-term investment pay off as oil production increased. However, when a CO2 compressor fails, CO2 volumes to the pipeline plummet by 50% or more. The operator needed predictive intelligence to prevent such an event.

|

|

Best Buy Slashes App Development Time And Resources With Xively (GCP App)

Xively (Google)

Best Buy wanted to quickly develop and deploy apps to achieve business goals. Also, create apps that are scalable and low-maintenance.

|

|

Machine Condition Monitoring for a Caribbean Resort

Advantech B+B SmartWorx

A Caribbean resort has numerous buildings spread out across a scenic campus. One of the company's most important concerns is reliable air conditioning, as guests will be very upset if they are uncomfortable. Downtime is not an option. But if air conditioning equipment fails completely - a compressor, for example - the replacement has to be shipped in from another country at an inflated price. The resort realized that closely monitoring their equipment would enable preventative maintenance, and greatly extend the useful life of their air conditioning systems. But how do you monitor things like pumps and compressors when they have no network interface and they are scattered across a very wide area?

|

|

ThermalSpection™ CVM

Advanced Energy

Critical vessels in the chemicals, refining, and power industries operate at high temperature and pressure and are at risk of failure as joints and refractory degrade. The consequences of undetected failures can be very serious. Conventional methods of real-time monitoring are unreliable and expensive to install and operate.

|

|

GWG Equipment Maintenance System for Automotive Manufacturers

Manufacturers require a centralised view on all its equipment and assets in order to enable capabilities such as RCM and TCM to maximise uptime and productivity. There is potential along the manufacturing process to reduce inventory redundancies, wastage in areas of MRO, and maximise utility of the different skill-sets among engineers, all of which are factors directly affecting the OEE of the manufacturing process.

|

|

Car Manufacturer Test IoT Solution on Test Vehicles

Faltcom

For each new model, Volvo Cars builds a number of test cars that are driven for a long time in a variety of locations around the world. The test cars gather data that are useful during the development of the car and Volvo Cars wanted online access to this data. Volvo Cars set a number of requirements for the solution: it had to be built on standards to allow for quick implementation and expansion, and it needed to maintain the highest security standards – an obvious requirement in light of the fierce competition in the automotive industry.

|

|

Equipment Monitoring/ Data reporting for Integrated Energy Company

Chirp

Our client (confidential), a major provider of Nuclear Energy in the UK and Europe were looking to enable equipment monitoring and data reporting capabilities in their nuclear facilities for increased operational efficiency. In these facilities, the use of Radio Frequency based networking is prohibited and therefore, an alternative solution was required.

|

|

WERMA GAUDLITZ Success Story in China

Werma

Gaudlitz was looking to achieve a lean management and production approach so as to improve production efficiency. Workers in the night shift were also taking a very long time to collect data.

|

|

Connection Listing

ZIN Technologies

Bosch security systems offer solutions with pre-installed connections in it, which is tested once before it’s made available for sale. Now when they have sold the solution they had to made sure its working and there is no loss in connectivity. Bosch security due to its nature of business has to keep track of where the said device is installed so they can troubleshoot in case of any issues. Now to keep track of more than 10,000 devices is a hard thing if you do not have any reference against devices. Bosch needed a solution where they can add information against each connection about its specific location and could see at a single glance if it's working or not.

|

|

Shuyang ITAD Household Waste Treatment Center Integrated Automated System

HITE

Shuyang ITAD household waste treatment center is a large environment facility with intensive and high integrated techniques. To meet the requirement to urban household waste modern integrated treatment and the treatment center scientific management, in the processing design, philosophy and technology about multi-points processing control and automated production line system control have been widely used.

|

|

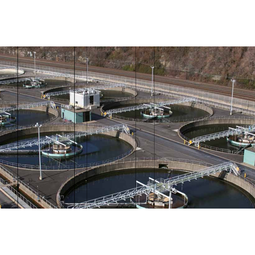

ECOsine Active Increased Grid Quality for Water Treatment facilities

Central wastewater treatment facilities need to meet stringent requirements in order to operate reliably and in an environmentally compliant manner. The responsible persons have. in particular, to ensure the availability of the plant on a 24/7 schedule. Numerous variable speed drives fro pumps and fans generate a harmonic content of the current in the supply that can lead to thermal overlkad of the electrical infrastructure and to malfunctions of sensitive equipment. In this application example, the power factor correction equipment suffered from significant additional losses caused by the harmonics.

|

|

NESTLÉ USES WIN-911 PRO MOBILE ALERTS FOR REFRIGERATION ALARMS RESULTING IN LESS

WIN-911

Nestlé needed to minimize downtime at their ice cream freezing facilities. Prior to the installation of WIN-911, offsite technicians took up to an hour to respond to alarms which could serve as a health hazard.

|

|

TRW calls for action with the help of WERMA

Werma

TRW needed a wireless monitoring system as laying cables and trunking throughout their sprawling and ageing facility would be an unimaginable task.

|

|

TOBYHANNA ARMY DEPOT DEPLOYS WIN-911 SOFTWARE WITH TRIDIUM’S NIAGARA PLATFORM

WIN-911

The installation of WIN-911’s alarm notification software at the Tobyhanna Army Depot was done as part of an overall energy efficiency project. In the early 2000s, the base worked to decentralize their coal-fired steam heating plant. This project included the construction of 10 boiler rooms housing 21 new boilers, as well as 37 air rotation units installed in various buildings. The entire infrastructure had to be integrated into HMI/SCADA systems and the existing control systems had to be upgraded. Ameresco, a leading independent energy efficiency company, was selected to head the project. Ameresco, in turn, specified WIN-911’s alarm notification system as the software platform used to instantly alert staff of any problems.

|

|

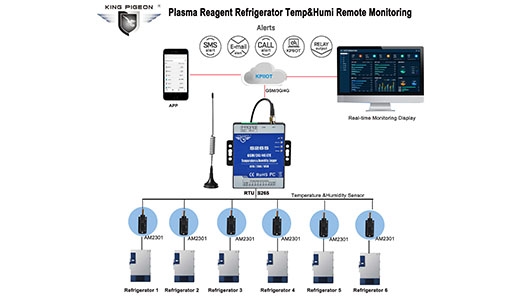

Temperature and humidity monitoring solution

温湿度监控解决方案血液站属于医疗卫生机构,负责收集和储存血液并将血液提供给临床或血液制品生产单位。因此,血液站中心的血液非常宝贵。温度和湿度环境对于确保血液在血液站中的安全非常重要。

|