Boeing Cuts Production Time by 25% with Skylight on Glass

- Analytics & Modeling - Virtual & Augmented Reality Software

- Wearables - Augmented Reality Glasses, Headsets & Controllers

- Aerospace

- Discrete Manufacturing

- Augmented Reality

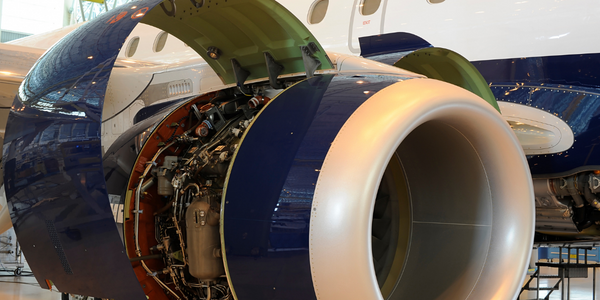

130 miles of wiring go into every new Boeing 747-8 Freighter, tucked away overhead and underfoot from the cockpit to the wheel wells.

Every Boeing aircraft, from the workhorse 737 to the new 787 Dreamliner, has multiple configurations, each with its own wiring scheme. In past years, technicians used “phone books” full of diagrams to do their work. Even with laptops, the same basic problem arised: constant look-away interruptions as workers got directions and cross-checked diagrams and schematics.

Skylight gives Boeing’s technicians the instructions they need right in their viewfinder. No need to look away or tap a laptop: they can move through multiple prompts with voice commands, the Glass touchpad, and the head tracking interface. A simple voice command like “local search 1-8-6-A” calls up the correct step-by-step schematic for every last wire.

Related Case Studies.