Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,158)

- (2,048)

- (1,256)

- (927)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,461)

- (1,423)

- View all 42 Industries

- (5,782)

- (4,114)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,392)

- (2,982)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,927 case studies

|

IoT-based Fleet Intelligence Innovation

Tata Communications

Speed to market is precious for DRVR, a rapidly growing start-up company. With a business model dependent on reliable mobile data, managers were spending their lives trying to negotiate data roaming deals with mobile network operators in different countries. And, even then, service quality was a constant concern.

|

|

HEINEKEN Uses the Cloud to Reach 10.5 Million Consumers

Microsoft

For 2012 campaign, the Bond promotion, it planned to launch the campaign at the same time everywhere on the planet. That created unprecedented challenges for HEINEKEN—nowhere more so than in its technology operation. The primary digital content for the campaign was a 100-megabyte movie that had to play flawlessly for millions of viewers worldwide. After all, Bond never fails. No one was going to tolerate a technology failure that might bruise his brand.Previously, HEINEKEN had supported digital media at its outsourced datacenter. But that datacenter lacked the computing resources HEINEKEN needed, and building them—especially to support peak traffic that would total millions of simultaneous hits—would have been both time-consuming and expensive. Nor would it have provided the geographic reach that HEINEKEN needed to minimize latency worldwide.

|

|

NB-IoT Street Lighting in China

China Mobile

In the past, sodium lamps have been expensive to install and maintain, requiring manual inspection and manual controls.

|

|

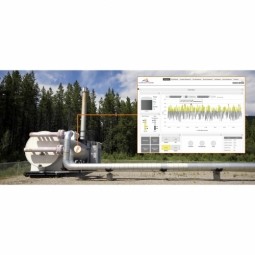

Asset Management and Predictive Maintenance

Litmus Automation

The customer prides itself on excellent engineering and customer centric philosophy, allowing its customer’s minds to be at ease and not worry about machine failure. They can easily deliver the excellent maintenance services to their customers, but there are some processes that can be automated to deliver less downtime for the customer and more efficient maintenance schedules.

|

|

Cutting-edge Predictive Analytics for HIROTEC Group

ThingWorx

Hirotec needed to ensure continuous operations and to minimize unplanned downtime in its manufacturing facilities. Unplanned downtime is costly and compromises Hirotec's ability to deliver its goods to customers on time.

|

|

Buoy Status Monitoring with LoRa

SmartLog

The Netherlands are well-known for their inland waterways, canals, sluices and of course port activities. The Dutch Ministry of Infrastructure indicates that there are thousands of buoys and fixed items in and near water environments that would profit from IoT monitoring. One of the problems with buoys for example, is that they get hit by ships and the anchor cable breaks. Without connectivity, it takes quite some time to find out that something has happened with that buoy. Not to mention the costs of renting a boat to go to the buoy to fix it. Another important issue, is that there is no real-time monitoring of the buoys at this moment. Only by physically visiting the object on the water, one gains insight in its status.

|

|

China Mobile Smart Parking

China Telecom

Smart Parking, powered by NB-IoT technology, is making it easier for drivers to find free parking spots. Cities can better manage their parking assets and maximize the revenue available to them as a result. Drivers searching for parking create congestion and pollution by circling and hunting for available parking. Smart Parking services are able to significantly ease these problems by guiding a driver directly to a parking space.

|

|

E.ON Gets Faster, Lower Cost Cycles with OpFlex Solutions

General Electric

E.ON's plants ran 4000+ hours per year, now see fewer than 1000+ hours of profitable operation. E.ON needed a fast, reliable and low-cost cycle plants.

|

|

Barcelona Case Study

Worldsensing

Barcelona’s heavy traffic and its associated high levels of pollution were the primary factors that motivated some companies and universities to work on strategies for improving traffic in the city centre. Bitcarrier is one of the technologies involved in the In4Mo Project, whose main objective is to develop the applications that form the core of smart mobility, one of the fundamental pillars of the smart city concept.

|

|

Digitize Railway with Deutsche Bahn

KONUX

To reduce maintenance costs and delay-causing failures for Deutsche Bahn. They need manual measurements by a position measurement system based on custom-made MEMS sensor clusters, which allow autonomous and continuous monitoring with wireless data transmission and long battery. They were looking for data pre-processing solution in the sensor and machine learning algorithms in the cloud so as to detect critical wear.

|

|

DeviceLynk Delivers Customized IIoT Solution

ThingWorx

Previously to working with ThingWorx, DeviceLynk built an IIoT platform but found it lacked scalability. They needed something to capture and handle data from an unlimited amount of devices and customers.

|

|

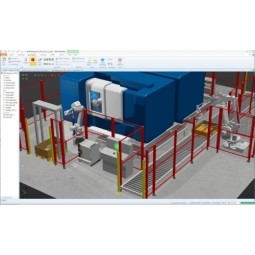

RobotStudio Case Study: Benteler Automobiltechnik

ABB

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.

|

|

OneWireless Enabled Performance Guarantee Test

Honeywell

Tata Power's power generation equipment OEMs (M/s BHEL) is required to provide all of the instrumentation and measurement devices for conducting performance guarantee and performance evaluation tests. M/s BHEL faced a number of specific challenges in conducting PG tests: employing high-accuracy digital communications for instrumentation, shortening setup and dismantling time, reducing hardware required, making portable instrument setup, avoiding temporary cabling work and the material waste costs

|

|

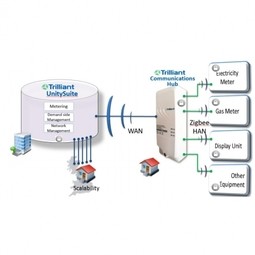

British Gas Modernizes its Operations with Innovative Smart Metering Deployment

Trilliant

The UK government has mandated that smart meters are rolled out as standard across Great Britain by end of 2020, and this roll-out is estimated to create £14 billion in net benefits to the UK in consumer energy savings and lower energy generation demand, according to the Oxford Economics report, “The Value of Smart Metering to Great Britain.” While smart-metering systems have been deployed in many countries, the roll-out in Great Britain is unique because it is led by energy retailers, who have responsibility for the Electricity and Gas meters. The decision to have a retailer-led roll out was made by DECC (Department of Energy and Climate Change) to improve customer experience and drive consumer benefits. It has also led to some unique system-level requirements to support the unique local regulatory model.

|

|

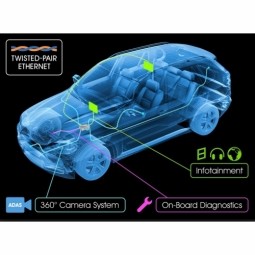

Rolls Out Second-Gen Automotive Switch with BroadR-Reach

Broadcom

Carmakers are facing the next wave of automotive connectivity. Cars will extend their reach, tapping our homes, talking to nearby cars and connecting to myriad other devices. New challenge is to meet bandwidth demands.

|

|

Cold Chain Transportation and Refrigerated Fleet Management System

Bright Wolf

1) Create a digital connected transportation solution to retrofit cold chain trailers with real-time tracking and controls. 2) Prevent multi-million dollar losses due to theft or spoilage. 3) Deliver a digital chain-of-custody solution for door to door load monitoring and security. 4) Provide a trusted multi-fleet solution in a single application with granular data and access controls.

|

|

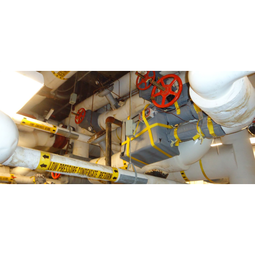

H800L IoT Ball Valve

Ham-Let

Ham-Let is a leading manufacturer of valves, fittings and instrumentation. One of the key challenges in this industry is identifying malfunctions and shutting off the appropriate valves before any damage can be done. However, it is often a demanding task to identify the cause of the malfunction and isolate the valves quickly.

|

|

Vending Machine Secure Real-time Data Using Everyware Cloud

Eurotech

As vending machine technology has evolved, it has become more challenging, less reliable and costly to connect phone lines to vending machines and collect data via a modem. Manual equipment maintenance is very costly, slow and labor intensive.

|

|

IoT Transforming Agribusiness

SAP

In order to achieve its goal of increasing agricultural yield in Brazil, Stara had the following objectives: • Establish technically robust operations for SAP® SuccessFactors® solutions • Increase technical stability • Improve performance and business throughput • Introduce efficient maintenance of software after the going-live event

|

|

Greenhouse Intelligent Monitoring and Control Solution

Advantech

Farming Orchids is the most successful form of precision farming in Taiwan, and also the most exported flower. Orchids need a specific temperature and humidity conditions to grow and bloom, and its flowering time may not be in line with market demands, so the price collapses when there is overproduction. Therefore, some farmers began to import automated greenhouse control systems for breeding and forcing, which not only improves quality, but also effectively controls the production period and yield to ensure revenue. In 2012, an orchid farmer built a Forcing Greenhouse of about 200 pings (approximately 661 Square Meters) in Tainan, Taiwan. The system integrator adopted Advantech’s APAX-5000 series programmable automation controllers to build the control platform, coupled with Advantech WebAccess HMI/SCADA software, to achieve cloud monitoring. The staff of the orchid field can monitor important data anytime via smart phone, iPad, and other handheld devices, and control the growth and flowering conditions. System requirements: In the past, most environmental control systems of orchid greenhouses in Taiwan used PLCs (Programmable Logic Controller) with poorscalability and control, and could not be connected to the Internet formonitoring from the cloud. For advanced database analysis and networking capability, the PC platform must be adopted. Therefore, PAC Systems (Programmable Automation Controller) with both PLC programming capabilities andPC functions is a better choice.The environmental control of the Orchid greenhouse switches on and off devices like fan, shade net, cooling/heat pump, liquid flow control, water-cooling wall etc. It is controlled by a control panel of electric controllers, and is driven by a motor, to adjust the greenhouse temperature, humidity, and other environmental conditions to the set parameters.

|

|

SCADA Cyber Security Vulnerability Assessment

Honeywell

A U.S. power company employed regularly-recurring audits of various controls, systems and programs. However, when it came to a SCADA-based cyber security vulnerability assessment, the in-house audit team did not possess the specific combination of process control experience and cyber security risks. They realized they required a third-party expert with a unique combination of knowledge of the two worlds.

|

|

IoT for Food Processing Machine Monitoring

The market where the Minerva Omega Group operates is almost mature and subjected to competitive pressures almost mature and subjected to competitive pressures from Asian low-cost manufacturers. Typically if competitors offer prices, the average customer tends to buy products that cost less, even though they have higher maintenance costs and TCO.

|

|

Thingworx Helps EET Monitor Real-Time Energy Savings

ThingWorx

Embedded Energy Technology (EET) wanted to build a dashboard for their customers to visualize the data analytics for the stream systems. They wanted the readings collected from the sensors to provide a complete picture of what is happening inside the component, and are displayed in a Web Portal that analyzes and presents the data in a concise format. The dashboard interface will also let customers set up email and text message alerts to be triggered when temperatures of the sensors customer select fall outside of the range they set. Summary reports are emailed monthly that highlight total energy savings, component health and month-over-month / year-over-year comparisons.

|

|

Temperature monitoring for vaccine fridges

Eseye

Dulas wanted a way to improve the reliability of the cold chain, facilitating maintenance and ensuring fewer vaccines are spoiled. Dulas wanted an M2M solution which would enable them to record and report the temperature inside vaccine refrigerators.

|

|

Intelligent Building Automation System and Energy Saving Solution

Advantech

One of the most difficult problems facing the world is conserving energy in buildings. However, it is not easy to have a cost-effective solution to reduce energy usage in a building. One solution for saving energy is to implement an intelligent building automation system (BAS) which can be controlled according to its schedule. In Indonesia a large university with a five floor building and 22 classrooms wanted to save the amount of energy being used.

|

|

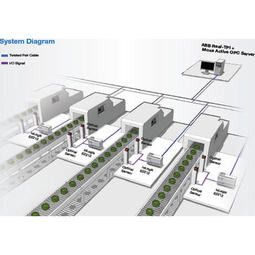

Improving Production Line Efficiency with Ethernet Micro RTU Controller

MOXA

Moxa was asked to provide a connectivity solution for one of the world's leading cosmetics companies. This multinational corporation, with retail presence in 130 countries, 23 global braches, and over 66,000 employees, sought to improve the efficiency of their production process by migrating from manual monitoring to an automatic productivity monitoring system. The production line was being monitored by ABB Real-TPI, a factory information system that offers data collection and analysis to improve plant efficiency. Due to software limitations, the customer needed an OPC server and a corresponding I/O solution to collect data from additional sensor devices for the Real-TPI system. The goal is to enable the factory information system to more thoroughly collect data from every corner of the production line. This will improve its ability to measure Overall Equipment Effectiveness (OEE) and translate into increased production efficiencies. System Requirements • Instant status updates while still consuming minimal bandwidth to relieve strain on limited factory networks • Interoperable with ABB Real-TPI • Small form factor appropriate for deployment where space is scarce • Remote software management and configuration to simplify operations

|

|

PC Control Combines PLC with CNC

Beckhoff

Kraft Maschinenbau produces highly customized doors, requiring very flexible, mixed production of a large variety of components and products, down to batch size 1. This includes variations in frame size, materials, décors, seal types, and fittings.

|

|

Asset Management helps NASCAR Drive Down Costs

Schneider Electric

Hendrick Motorsports wanted to coordinate information across 6 warehouses, track usage of approximately 150 components on each car and get the system up and running within four months.

|

|

Data Warehouse for Sales and Inventory Management | Dial

Informatica

Dial needed a solution that would: improve sales performance, establish more effective sales promotions and product distribution strategies, reduce IT support and increase agility, and lower costs: new requirements for data were expensive and slow to turn around.

|

|

Aerospace & Defense Case Study Airbus

Dassault Systemes

For the development of its new wide-body aircraft, Airbus needed to ensure quality and consistency across all internal and external stakeholders. Airbus had many challenges including a very aggressive development schedule and the need to ramp up production quickly to satisfy their delivery commitments. The lack of communication extended design time and introduced errors that drove up costs.

|