Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,158)

- (2,048)

- (1,256)

- (927)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,461)

- (1,423)

- View all 42 Industries

- (5,782)

- (4,114)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,392)

- (2,982)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,927 case studies

|

Cognitive Analytics for Oil and Gas

SparkCognition

Oil and gas companies are having problems learning from the data to understand the different operational states and failure modes of assets, and uses this learning to provide adequate warning before failures occur so operators can plan for corrective actions thus optimizing their Operations and Maintenance budgets.

|

|

Enabling Internet of Things Innovation in Agriculture

Digi

DigiBale, wanted to apply technology know-how and IP from implementations successfully to more agriculture sectors including cotton, forestry, sugarcane and cattle. However, farmers and growers still have worries about the connected technology.

|

|

Powering Smart Home Automation solutions with IoT for Energy conservation

Saviant

Many industry leaders that offer Smart Energy Management products & solutions face challenges including:How to build a scalable platform that can automatically scale-up to on-board ‘n’ number of Smart home devicesData security, solution availability, and reliability are the other critical factors to deal withHow to create a robust common IoT platform that handles any kind of smart devicesHow to enable data management capabilities that would help in intelligent decision-making

|

|

ABB Integrates Kepware Communication Platform for Well Sites

Kepware (PTC)

One of the biggest technical challenges ABB faced with this project was automating the collection of well data. The project called for between 1,000 and 1,500 well sites to come online in 2014, and beyond 6,000 by 2030, over an area of more than 4,500 km². Each of these wells have between 50 and 70 data points being scanned on a 30-second cycle time. With several new wells being introduced every day, ABB needed to be able to bring them on and off line in a highly streamlined and efficient manner; furthermore, the method of configuring them needed to be simple, fast, and very reliable. It also needed to be able to reliably retrieve vast amounts of data from distant locations. All this meant that the automation of data collection was a huge undertaking, since the project infrastructure was immense and constantly in flux. To handle these requirements, ABB needed an automated communications platform that was highly reliable and that could easily scale and communicate massive amounts of data back for visualization and long-term storage in an enterprise historian.

|

|

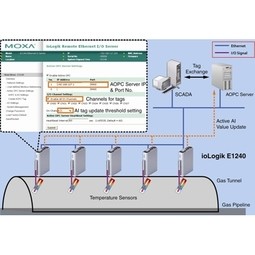

Remote Gas Pipeline Tunnel Temperature Monitoring System

MOXA

One of Singapore's leading engineering and system integration providers needed exactly the right solution for a challenging gas pipeline application. With experience in assembling systems for many different vertical markets such as oil and gas networks, factory automation, and building automation, this system integrator realized that monitoring the temperature of a gas pipeline tunnel is crucial for safe operations. In the confined space of a tunnel, temperature rises easily, and the overheating could cause pipeline fractures that could lead to gas leaks or even explosions. Meanwhile, the long and narrow dimensions inherent to a tunnel meant that more home run cables must be installed to link all the temperature gauge data acquisition I/O devices back to the pipeline's SCADA system, increasing cabling costs. With these stakes and in these conditions, the simple act of regularly taking the temperature transforms into a formidable yet absolutely necessary requirement. System Requirements • Real-time tunnel temperature monitoring to provide early excessive heat warnings • Data acquisition and system management with SCADA system • Ethernet data acquisition system, but with efficient, cost-effective wiring

|

|

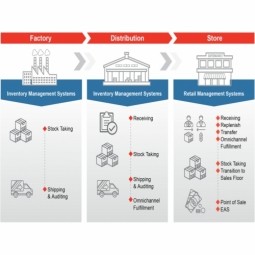

SML Intelligent Inventory Solutions

Microsoft

SML Intelligent Inventory's customers, some retail and supply chain businesses wanted a cost-efficient way to improve their inventory management so that they can increase their revenue.

|

|

Vehicle Fleet Analytics

C3 IoT

Organizations frequently implement a maintenance strategy for their fleets of vehicles using a combination of time and usage based maintenance schedules. While effective as a whole, time and usage based schedules do not take into account driving patterns, environmental factors, and sensors currently deployed within the vehicle measuring crank voltage, ignition voltage, and acceleration, all of which have a significant influence on the overall health of the vehicle.In a typical fleet, a large percentage of road calls are related to electrical failure, with battery failure being a common cause. Battery failures result in unmet service agreement levels and costly re-adjustment of scheduled to provide replacement vehicles. To reduce the impact of unplanned maintenance, the transportation logistics company was interested in a trial of C3 Vehicle Fleet Analytics.

|

|

BMW Story Spare Part Logistics

ProGlove

|

|

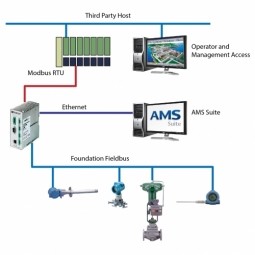

Advanced Elastomer Systems Upgrades Production

Emerson

In order to maintain its share of the international market for thermoplastic elastomers AES recently expanded its Florida plant by adding a new production line. While the existing lines were operating satisfactorily using a PROVOX distributed control system with traditional analog I/O, AES wanted advanced technology on the new line for greater economy, efficiency, and reliability. AES officials were anxious to get this line into production to meet incoming orders, but two hurricanes slowed construction.

|

|

Continuous Casting Machines in a Steel Factory

Advantech

With a very broad range of applications, steel is an important material and has been developed into the most extensive alloy in the engineering world. Since delivering high quality is absolutely crucial for steel plants, ensuring maximum productivity and the best quality production are the keys to competitiveness in the steel industry. Additionally, working conditions in steel factories are not suitable for workers to stay in for long periods of time, so manufactures usually adopt various machines to complete the steel production processes. However, the precision of these machines is often overestimated and the lack of flexibility also makes supervisors unable to adjust operating procedures. A renowned steel factory in Asia planned to improve its Distributed Control System (DCS) of furnaces as well as addressing the problem of insufficient accuracy. However, most well-known international equipment suppliers can not provide a satisfactory solution and local maintenance because the project needed new technologies to more accurately control equipment operations. By implementing Advantech’s automated monitoring and control solution, steel factories can not only improve the manufacturing processes but can also allow users to add additional functions to the existing system so as to make sure the operation runs at high efficiency.

|

|

Drone Connectivity and Parachute Deployment for Flying Eye

Digi

Around the world, drones of all shapes and sizes from the market-pioneering Flying Eye are filling the skies. They incorporate a wide range of sensors, cameras, batteries, and radio controls, making them an increasingly valuable proposition to a broad cross-section of industries. Today, Flying Eye drones are spraying crops, capturing breathtaking photos and videos of remote locations, and extending the reach and agility of customers around the world. But, according to Alexandre Thomas, co-founder and technical director of Flying Eye, significant safety issues emerge as these tiny aircraft crisscross overhead, since these vehicles are often flying quite near crowds of people. “A drone must be safe, and designers must have contingencies in place to respond to unplanned events and failures,” he said. “We take a lot of measures to ensure reliability in our aircraft. Our electronics are tested to ensure the drone won’t unexpectedly shut down. We design propellers from durable materials, and we invest in battery technology to keep the drones aloft for longer periods of time.” Of course, no vehicle is 100-percent foolproof. Technical errors and operator errors can disrupt flights, which is why Flying Eye builds in contingency parachutes and redundant communications into its aircraft. And that’s where Digi XBee® RF modules play a key role.

|

|

Power Analytics for Power Plant

Given low power prices maintained by stagnant demand growth, a customer’s combined cycle power plant was staffed as leanly as possible. As such, a change in operational parameters went unnoticed by engineers at the plant.

|

|

Industry 4.0 and Smart Manufacturing

Bright Wolf

A potent innovator of filtration technology, the company had little experience with information technology, and no in-house expertise for bringing digital products to market. The company needed an information technology partner with deployment experience spanning industrial hardware, protocols, and the cloud to assist in their journey to becoming a connected products solution provider.

|

|

Gas Pipeline Monitoring System for Hospitals

MOXA

This system integrator focuses on providing centralized gas pipeline monitoring systems for hospitals. The service they provide makes it possible for hospitals to reduce both maintenance and labor costs. Since hospitals may not have an existing network suitable for this type of system, GPRS communication provides an easy and ready-to-use solution for remote, distributed monitoring systems System Requirements - GPRS communication - Seamless connection with SCADA software - Simple, front-end control capability - Expandable I/O channels - Combine AI, DI, and DO channels

|

|

Splunk Partnership Ties Together Big Data & IoT Services

ThingWorx

Splunk was faced with the need to meet emerging customer demands for interfacing IoT projects to its suite of services. The company required an IoT partner that would be able to easily and quickly integrate with its Splunk Enterprise platform, rather than allocating development resources and time to building out an IoT interface and application platform.

|

|

3M Gains Real-Time Insight with Cloud Solution

Microsoft Azure

The company has a long track record of innovative technology solutions. For example, 3M helps its customers optimize parking operations by automating fee collection and other processes. To improve support for this rapidly expanding segment, 3M needed to automate its own data collection and reporting. The company had recently purchased the assets of parking, tolling, and automatic license plate reader businesses, and required better insight into these acquisitions. Chad Reed, Global Business Manager for 3M Parking Systems, says, “With thousands of installations across the world, we couldn’t keep track of our software and hardware deployments, which made it difficult to understand our market penetration.” 3M wanted a tracking application that sales staff could use to get real-time information about the type and location of 3M products in parking lots and garages. So that it could be used on-site with potential customers, the solution would have to provide access to data anytime, anywhere, and from an array of mobile devices. Jason Fox, Mobile Application Architect at 3M, upped the ante by volunteering to deliver the new app in one weekend. For Fox and his team, these requirements meant turning to the cloud instead of an on-premises datacenter. “My first thought was to go directly to the cloud because we needed to provide access not only to our salespeople, but to resellers who didn’t have access to our internal network,” says Fox. “The cloud just seemed like a logical choice.”

|

|

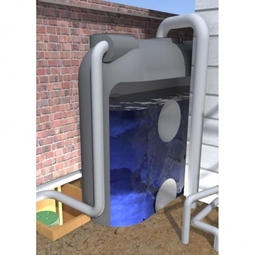

Rainwater Harvesting

Opti

The Twin Oaks branch of the Austin Public Library wanted to upgrade its existing rainwater harvesting system to improve its wet-weather performance.

|

|

Smart City Public Safety

Amyx+ worked with a local government authority to develop an Internet of Things-enabled public safety strategy. In the current state, vigilance meant manually scanning through potentially hundreds of analog surveillance videos feeds. Manual, costly and ineffective, the local agency desired to transition from analog to digital CCTV, apply computer vision and other technologies to automatically detect potential crime in progress, expedite and streamline emergency calls and integrate with personal wearables to ensure the safety of their citizens.

|

|

Precision beekeeping with wireless temperature monitoring

Aranet

Honeybees are insects of large economic value and provide a vital service to agriculture by pollinating a variety of crops. In addition, bees provide us with valuable products such as honey, beeswax, propolis, bee venom, etc. Monitoring of honeybee colony health, population, productivity, and environmental conditions affecting the colony health have always been exceedingly difficult tasks in apiculture. Research has shown that even small deviations (by more than 2°C) from the optimal temperatures have a significant influence on the development of the brood and the health of adult bees.

|

|

Energy Management System at Sugar Industry

Secure Meters

The company wanted to use the information from the system to claim under the renewable energy certificate scheme. The benefit to the company under the renewable energy certificates is Rs 75 million a year. To enable the above, an end-to-end solution for load monitoring, consumption monitoring, online data monitoring, automatic meter data acquisition which can be exported to SAP and other applications is required.

|

|

Transport Platform - Serving the Energy Data Management

Bosch

The challenge for EWZ was to design the processes so that they could be traced easily and meet the standards for handling exchange processes in line with the market such as automation of bulk data exchange and exchange processes as well as their implementation according to the SDAT and MC-CH industry documents, integration of the very heterogeneous IT landscape, and no in-house development but a tried and tested standard product.

|

|

IoT Based Asset Tracking System

Zerone Technologies

The existing system used by the customer could only track a few thousand assets and was able to generate only a few standard set of reports. As the number of assets tracked grew exponentially, the system started to break at the seams. The Tracking devices were from different manufacturers following different protocols. There was no proper integration among the devices to send instant alerts. There are thousands of tracking devices spread across multiple geographies, that are moving. The configuration and troubleshooting of these devices incurred heavy costs, which was a logistics challenge. The existing system did not provide sophisticated Analytics, Business Intelligence and Insights from the data

|

|

Automated Predicitive Analytics For Steel/Metals Industry

SORBA IoT

Asset to be monitored: Wire Compactor that produces Steel RebarCustomer Faced The Following Challenges:Dependent upon machine uptime.Pressure cylinders within the compactor fail to control compression and speed causing problems in binding the coil.Equipment failure occurs in the final stage of production causing the entire line to stop, can you say bottleneck?Critical asset unequipped with sensors to produce data.

|

|

Developing a MyCity Vision for a Digital Birmingham

Atos

Birmingham wanted to attract more investment, generate more employment, promote sustainability and offer a better quality of life to their citizens. Birmingham needed a solution that can solve the following problems: lack of statutory authority to enforce specific technology requirements, absence of universal standards to disparate networks, fragmented and incomplete GIS information about city utilities, bureaucratic nature of civic planning processes, rising demand for high-speed connectivity and need for more bandwidth and power for data-intensive services.

|

|

IoT Based Health Monitoring System

Zerone Technologies

The primary challenge was to monitor the progress of the plans adopted by the patients. In most cases, the patient will start with a plan and give up in the middle. It is important to motivate them to continue through the plan.

|

|

WestJet Oracle Exadata Technical Case Study

Oracle

WestJet wanted to grow Guest Self Service to 60% and implement a database platform that will provide WestJet's exceptional Guest Experience by 2016.

|

|

How Sirqul’s IoT Platform is Crafting Carrefour’s New In-Store Experiences

Sirqul, Inc

Carrefour Taiwan’s goal is to be completely digital by end of 2018. Out-dated manual methods for analysis and assumptions limited Carrefour’s ability to change the customer experience and were void of real-time decision-making capabilities. Rather than relying solely on sales data, assumptions, and disparate systems, Carrefour Taiwan’s CEO led an initiative to find a connected IoT solution that could give the team the ability to make real-time changes and more informed decisions. Prior to implementing, Carrefour struggled to address their conversion rates and did not have the proper insights into the customer decision-making process nor how to make an immediate impact without losing customer confidence.

|

|

Pitney Bowes Industrial Internet

GE Digital (GE)

The world's 1st-ever Industrial Internet platform, Predix, becomes a pathway for revenue generation and notable new cost savings for Pitney Bowes' production mail business. An ordinary mail business, this is not. Of the 150 million pieces of mail produced each day in the US, the majority go through Pitney Bowes machines.

|

|

Marine and Industrial Displays by Caterpillar

Bright Wolf

Caterpillar needed a flexible platform for a new generation of connected human-machine interfaces across a wide variety of industrial environments. Examples include marine, petroleum pumping, generators, custom hydraulics, mining, and rail applications.

|

|

Connected Sheep in Norway

Telia

On a typical sheep gathering session, 10-12 farmers face difficulties finding all their animals. The implication is that both animal and farmer may have to stay out for longer than necessary. When there is heavy snow, this compounds the problems and the cold induces distress upon both farmer and animal.

|